Small damage quickly repaired – even without entering the vessel

Small damage to nozzle necks of glass-lined process equipment can be repaired quickly and safely with the THALETEC EmRep System. Depending on the location of the damage, this is even possible without having to enter the glass lined reactor or tank – a significant time and cost advantage over other repair methods.

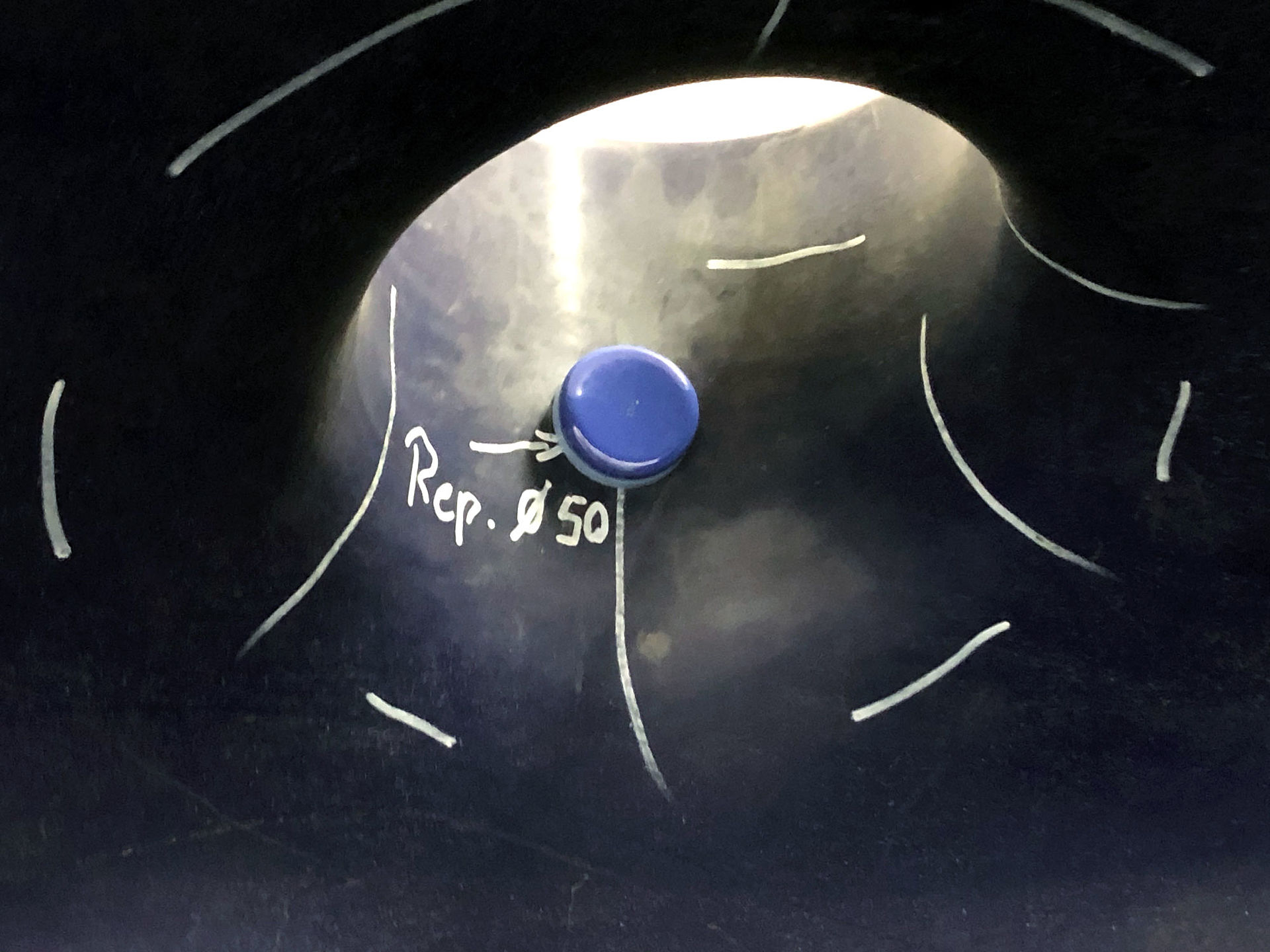

The picture shows a repaired area in a DN 200 nozzle. The repair element "RW" glass-lined with the highly chemically resistant and wear-resistant THALETEC ABRISIST covers a damage with a diameter of approx. 20 mm (0,8''). The repair element is fixed with a screw connection on the outside of the glass-lined body. This allows a quick and easy installation. The gasket can also be retightened at any time from the outside without opening or getting into the tank.

Further details about THALETEC Glass Repair Technology for glass-lined process equipment of all manufacturers can be found in Flyer K097.