Universal resistant RAS GLASS blue

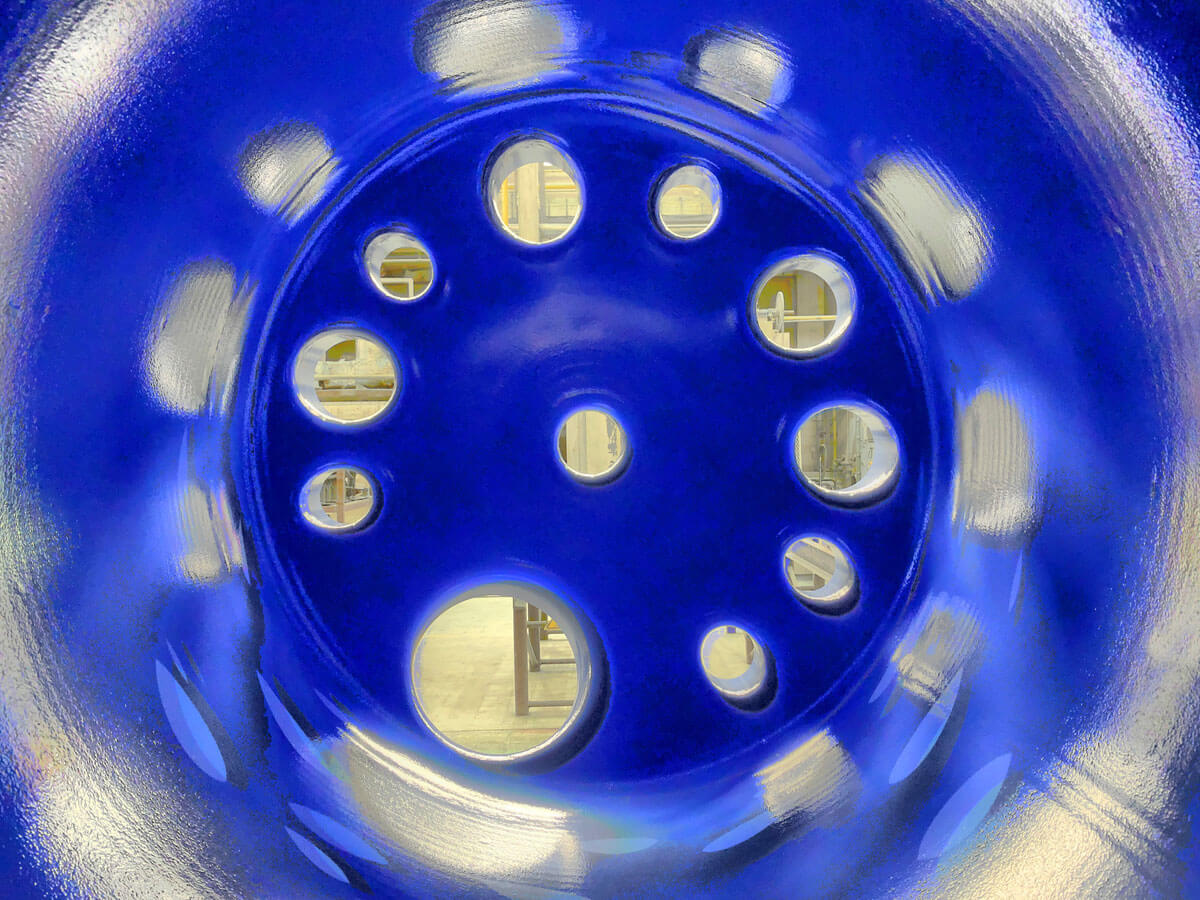

RAS Glass blue is the "workhorse" our glass linings for the process industry. This glass lining is almost universally applicable and has a dark blue or cobalt blue color. RAS Glass blue is universally chemicals resistant and can be used for the glass linings of all sorts of components and vessels.

Except for a few exceptions, RAS Glass blue is also used for the glass linings of our standardized spare parts, which match also the equipment of other manufacturers, that you can get from THALETEC. You find further details about it in Spare Parts on this site.

This glass lining has a high resistance for acid PH applications and is for the majority of applications also resistant for higher PH values.

RAS Glass blue is used mainly in general applications without pronounced requirements for cleanability or for the glass linings of storage tanks, receivers, columns or other equipment.

Electric Conductive CONDUSIST

THALETEC CONDUSIST is an electrically conductive glass-lining. It is used when process conditions or the media processed can cause the creation of electrical charges. CONDUSIST discharges the electrical charges before they can damage the glass-lining.

CONDUSIST can be applied to all parts. It makes sense though to apply CONDUSIST to parts only that are exposed to moving liquids inside a reactor or tank, such as the reactor itself, baffles and agitators.

Besides CONDUSIST, THALETEC offers more products and services around electrically charging processes, such as gaskets, CIP-Systems or Workshops.

Abrasion Resistant ABRISIST

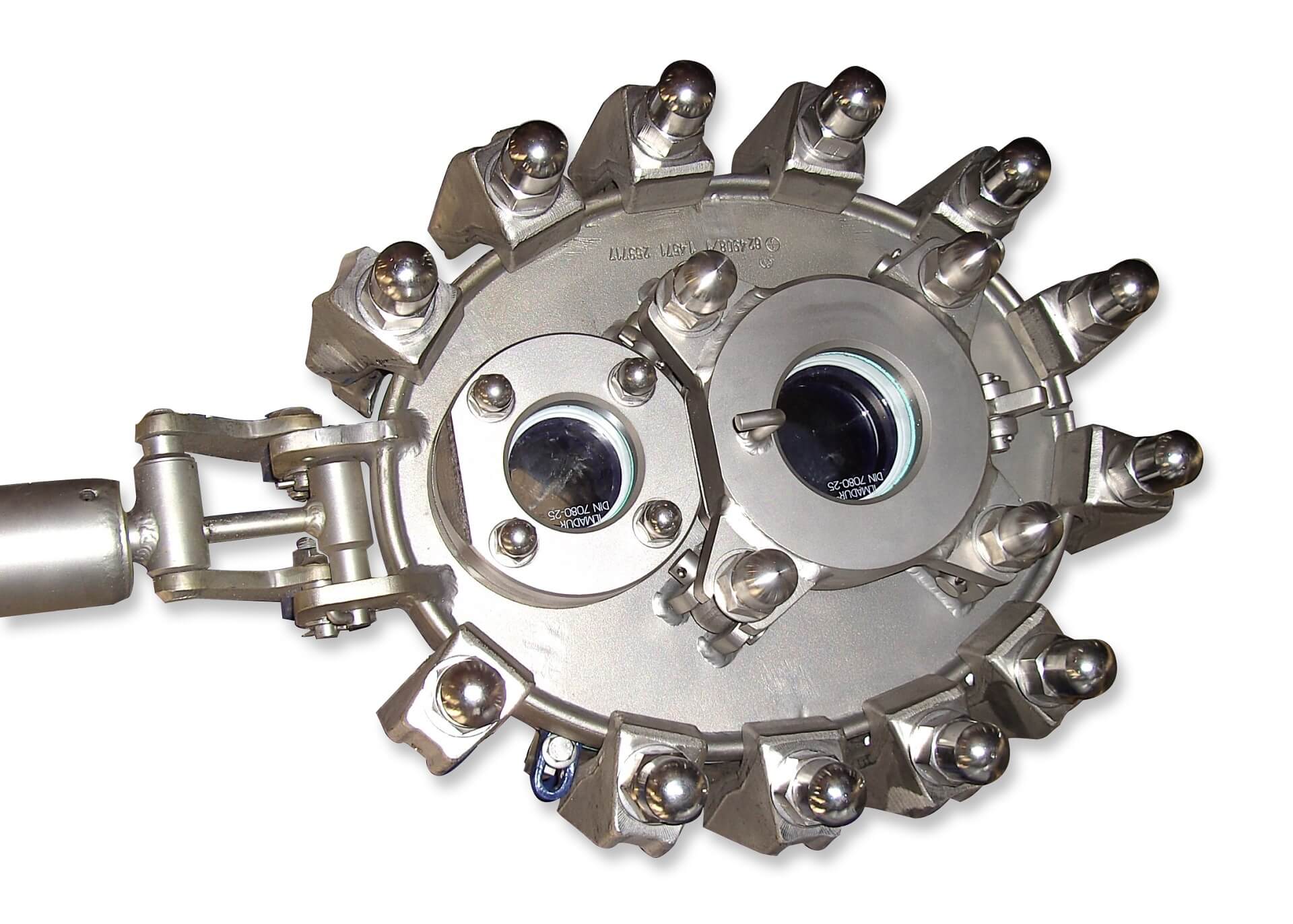

THALETEC ABRISIST is a glass lining for processes that subject to intense wear the glass coatings. Specifically hydro abrasive wear ocours for instance in stirring processes when solids are also present in the fluid. They can be or become suspending particles or cristals as a result of a destilllation or cristalization process.

THALETEC ABRISIST is available in the following types

• ABRISIST/b: Color medium boue, satin or shiny

• ABRISIST/w: Color pure white, satin or shiny

• ABRISIST/VC: Color middle blue satin or shiny with wear indicator

Besides the optimal glass lining with ABRISIST, other optimizations can be performed. Among them, the usage of optimized turbines and baffles.

THALETEC Polysist

Glass-lining for Polymerization Processe

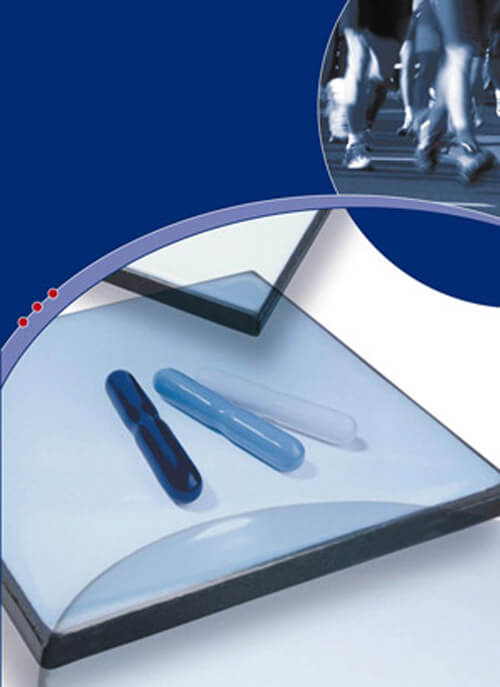

THALETEC Polysist is a new glasslining that has been specially developed for polymerization processes. Compared to other technical enamels and especially electro polished surfaces THALETEC Polysist has a significantly smoother and anti-adhesive surface. THALETEC Polysist also improves the heat transfer, which is important for the dissipation of reaction heat, compared to other chemical enamels.

The special properties of Polysist are achieved by additives to the enamel raw materials used.

Compared to electro polished metallic surfaces with Ra values of 0.4, the roughness of THALETEC Polysist is consistently only 15% of this value.

THALETEC Polysist can be used for all relevant glass-lined and product-wetted components (e.g. vessels, agitators, baffles, etc.).

THALETEC Alkasist

Extremely alkali-resistant glass-lining

THALETEC ALKALISIST is a newly developed enamel for processes where the pH value is (significantly) above 7 over long phases.

While common glass-linings have excellent chemical resistance in highly corrosive acidic processes, these glasses perform less well under basic conditions. This is mainly due to the basic properties of glass, which include glasslinings.

The durability of glass-linings is proven by standardized test methods. These make it possible to objectively compare enamels from different manufacturers. DIN EN ISO 28706 4:2011-08

applies to the proof of alkali resistance. According to this test method, THALETEC ALKALISIST has a corrosion rate that is 60% lower than the corrosion rate of a standard glasslining. Nevertheless, even in the acidic range (DIN EN SO 28706 2:2011-08), THALETEC ALKALISIST has a corrosion resistance that is within the permissible values according to DIN EN ISO 28721-1:2011-06.

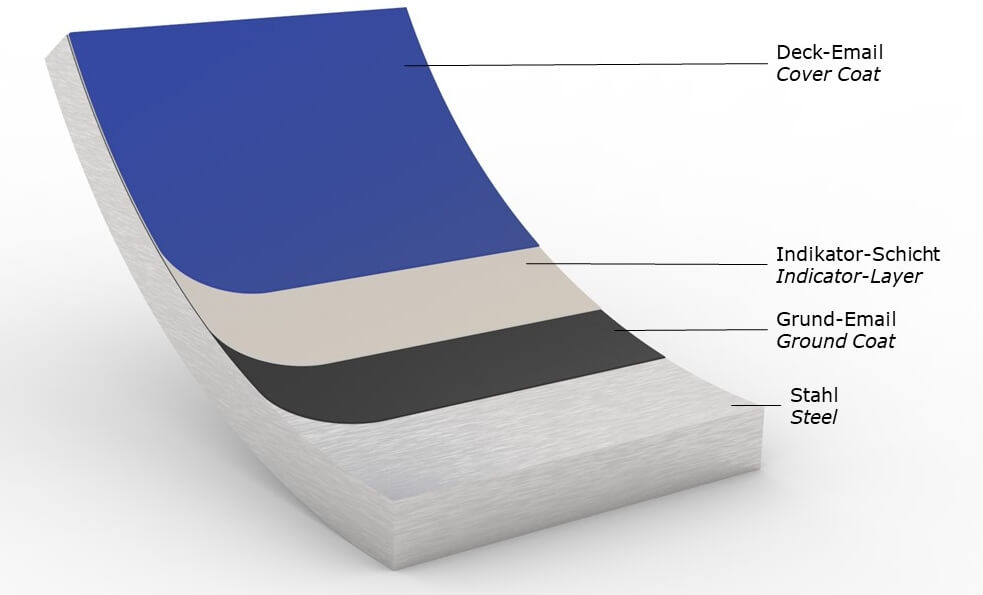

To increase the operational safety of components coated with THALETEC ALKALISIST and to detect critical glass erosion at an early stage, THALETEC ALKALISIST is produced in a multilayer process with an embedded indicator layer. If glass erosion occurs during use, it is easy to visually detect that the end of service life is approaching.

THALETEC RAS GLASS white

THALETEC RAS Glass white is a white colored, high quality and and highly resistant glass lining for chemical applications. The white color of this glass lining comes from a high filling level of resistant ceria.

White glass linings are mostly used by pharmaceutical industry. The light color facilitates the observation of the container level.

THALETEC ist the expert for glass linings, reglassing, glass for process industry & RAS GLASS white.

ESG 2000

ESG 2000 is a glass for the glass-lining of stainless steel parts. The glass is an universal glass and dark blue in color.

ESG is highly corrosion resistant against strong acids and can alo be used with higher pH-values.

ESG can be used for glass-lining selected components, such as manhole-covers.

For the production of API we recommend to use parts and reactors glass-lined with PharmaGlass TPE. Processes with high wear should use THALETEC's ABRISIST glass. In cas of teh occurence of electrical discharges, CONDUSIST is the right solution.