In particular, the excellent properties of the glass lining and the tube geometry with regard to mechanical stability and chemical resistance make THALETEC’s glass-lined heat exchangers a reliable and highly economical system.

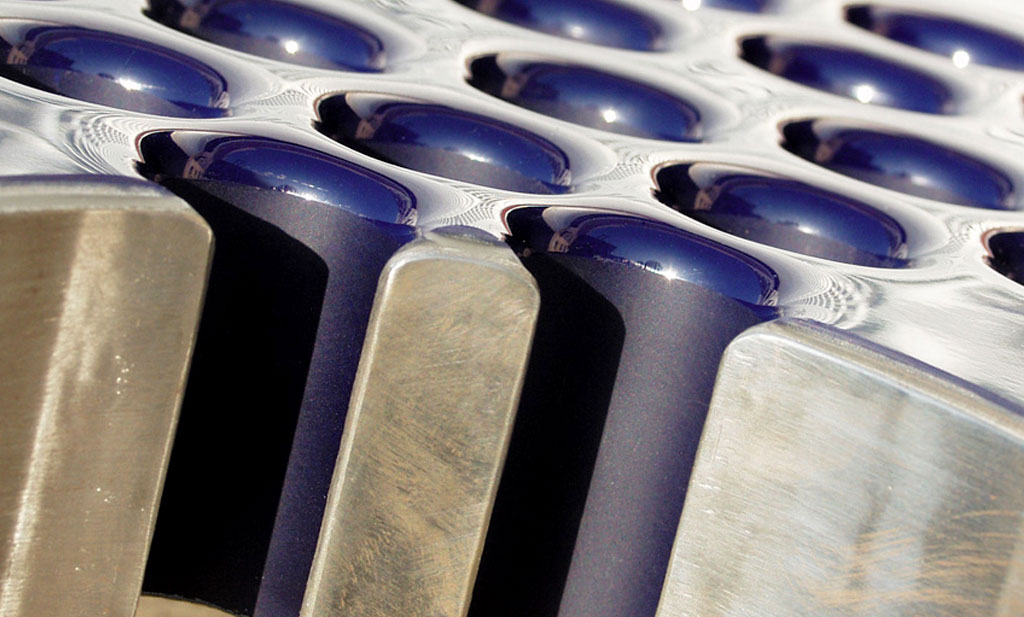

The outstanding feature of all THALETEC heat exchangers is the patented connection of the glass-lined tubes with the tube sheet: After the glass-lined tubes and the holes in the tube sheet, which are also glass-lined, have been ground to high precision, they are joined to each other using the principle of cross-press-bonding (shrink connection). The shrink connection ensures, on the one hand, a liquid tight and gas-tight connection. On the other, the connection is capable of absorbing high forces (Illustration 2).

In this context, it is particularly important to note that the connection between the tubes and the tube sheet is absolutely seal-free. Therefore, there is also no restriction in the application limits, as is the case with heat exchangers with sealing elements made of PTFE or perfluoroelastomers.

The tightness of the connection is individually verified and documented for each manufactured heat exchanger, regardless of its design (as a WTU heat exchanger or as a PowerBaffle).

At regular intervals, strength tests are additionally carried out on the tube/tube sheet connection. For this purpose, a test sample is produced and the force required to pull a pipe out of the hole is determined.

Illustration 4 shows a screenshot of the force-path diagram recorded during the test. It can be seen that the glass-lined tube initially stretches by about 1.8 mm without damaging the glass lining when the tensile force is applied. Only when a tensile force of about 32 KN (that is 3.2 tons!) is reached does the pipe detach.

Want some numbers?

Some numbers clearly illustrate the strength and stability of the connection between tubes and tube sheet:

With the given dimensions, the tensile test results in a release force of about 32,000 N per tube, viz. 3.2 tons. With this load applied as a tensile force to the individual tube, the tube shifts for the first time in the press fit.

If this release force is converted to a hydraulic pressure which should prevail inside the pipe, the result is a value of 1040 bar! This means that the heat exchanger tube would only come loose at an internal pressure of 1040 bar in the heat exchanger! At a normal operating pressure of 6 bar, this results in safety against failure of 173! Even at an internal pressure of 25 bar, the safety is still 42!

Due to the release force of about 3 tons, material utilisation in the pipe itself is only about 60%. The material or component has a very high stability reserve and strength reserve, which makes the heat exchanger system also suitable for applications subject to particularly high mechanical stress.

The experiment also showed that the pipe, after loosening for the first time, was still firmly in the press fit. The tightness of the connection is also guaranteed. This means that even if the connection is overloaded once, there is no total failure of the connection. The system can still be operated safely.

Conclusion

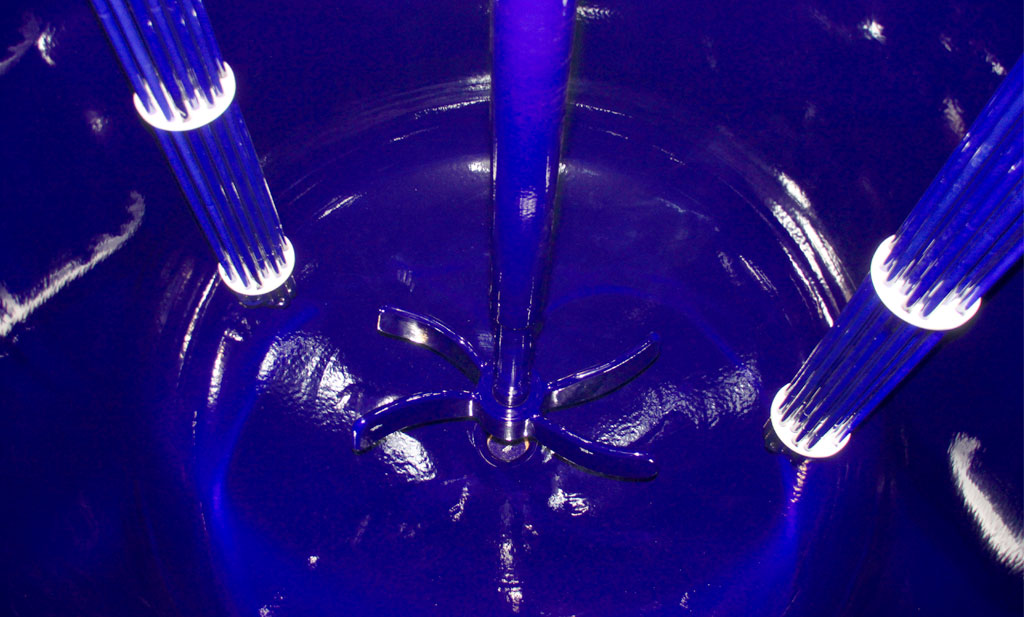

Glass-lined THALETEC heat exchangers are very efficient systems for heat exchange in chemically demanding applications. Regular testing of the technical and mechanical properties of the tube/tube sheet connection ensures consistently high quality and high operational safety. THALETEC heat exchangers are universally applicable in the chemical and pharmaceutical industries due to the seal-less tube/tube sheet connection with the aid of a shrink connection. The mechanically challenging application of heat exchangers as PowerBaffles (see video) is also mastered with high operational reliability.

If you would like to learn more about THALETEC's glass-lined heat exchangers, take a look at our workshop ‘Maximum heat exchange in glass-lined apparatus’ (Flyer K059).