THALETEC FlatFace nozzles for highest requirements

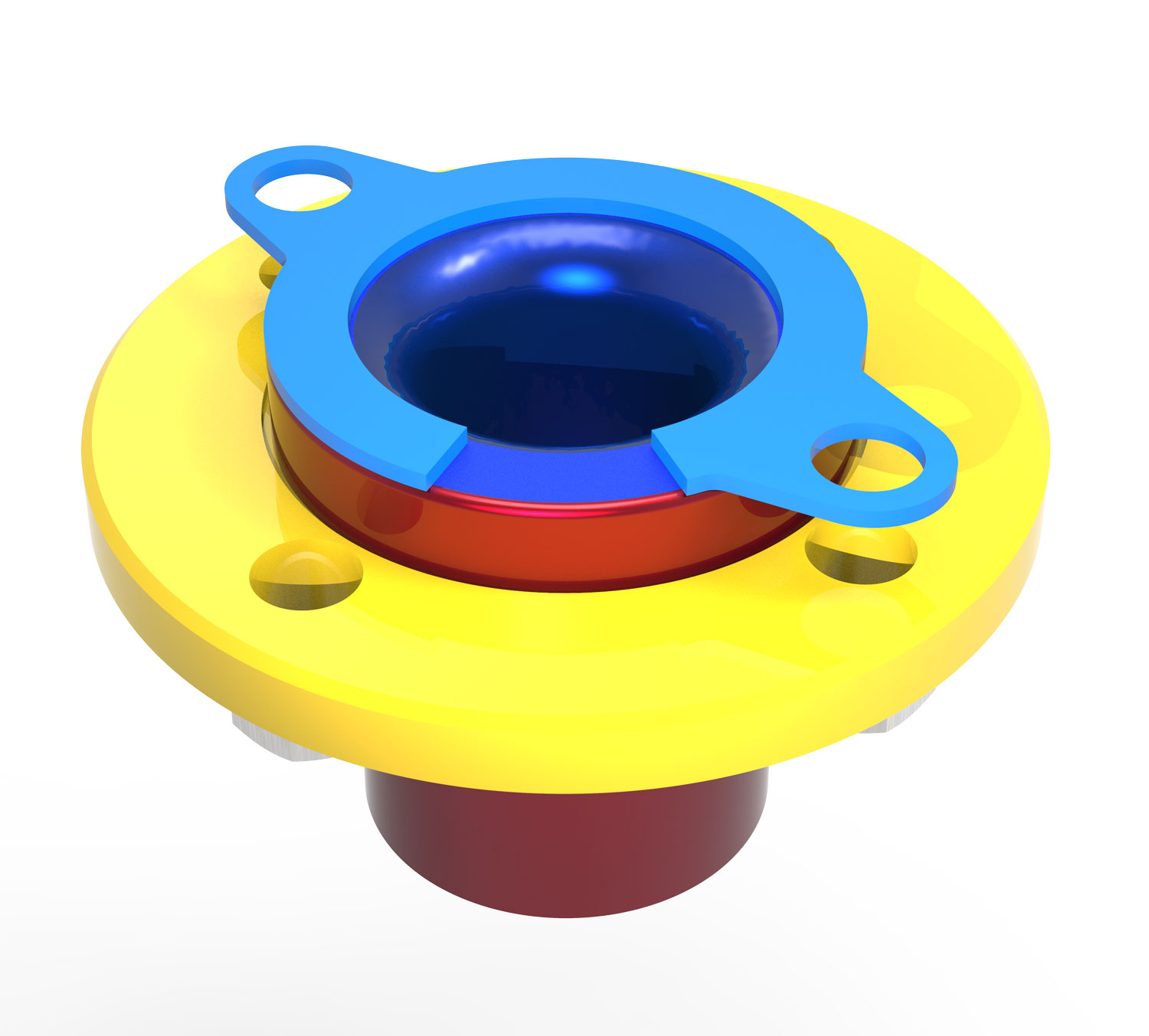

The sealing surface of smaller glass lined nozzles may be slightly crowned due to the specific properties of the glass-lining process (Fig. 1). Usually the crowning of the sealing surface has no influence on the sealing effect of flange gaskets, provided that they are suitable for glass- lined nozzles.

Applications where higher demands can be made on the flatness of the sealing surfaces are for example:

- Sealing under GMP conditions

- Sealing at pressures above 16 bar

- Use of gaskets made of expanded PTFE or comparable materials

- Use of monolithic gaskets made of PTFE or filled PTFE compounds

- Sealing of components made of PTFE or flange surfaces coated with PTFE

With the FlatFace technology THALETEC offers a solution for these applications: After firing the glass-coating, the flange surfaces of the nozzles are ground flat and plane-parallel by means of a precision grinding process. The manufacturing technology ensures that the minimum permissible glass layer thickness in the grinding area is not undercut. THALETEC FlatFace nozzles are available for nominal diameters up to and including DN 250 (10'').

NEW – FlatFace gaskets

For FlatFace nozzles there are now also the suitable flange gaskets available. These consist of 3.2 mm thick "Gylon blue" and are optimally matched to the dimensions of the FlatFace nozzles. In addition, the gaskets are equipped with an assembly aid that greatly simplifies installation and centering of the gasket on the FlatFace nozzle.

Further information on THALETEC FlatFace nozzles can be found in Flyer K133.