Deutsch

Deutsch  Englisch

Englisch

Energy Efficiency!

This newsletter is devoted in particular to the topic of energy efficiency. Read some posts that cover this topic. Find out which measures you can take to operate your glass-lined reactors in an energy-efficient manner.

You are also welcome to use our offer regarding process engineering design and calculation. We would be happy to determine with your specific task what effects measures to increase efficiency in stirring and mixing and heat transfer are possible.

A lot of money can also be saved when cleaning CIP enamelled apparatus. THALETEC helps you: With the help of modern simulation methods, we can help optimize the cleaning result. Ask us about CIPSim and read the further information below.

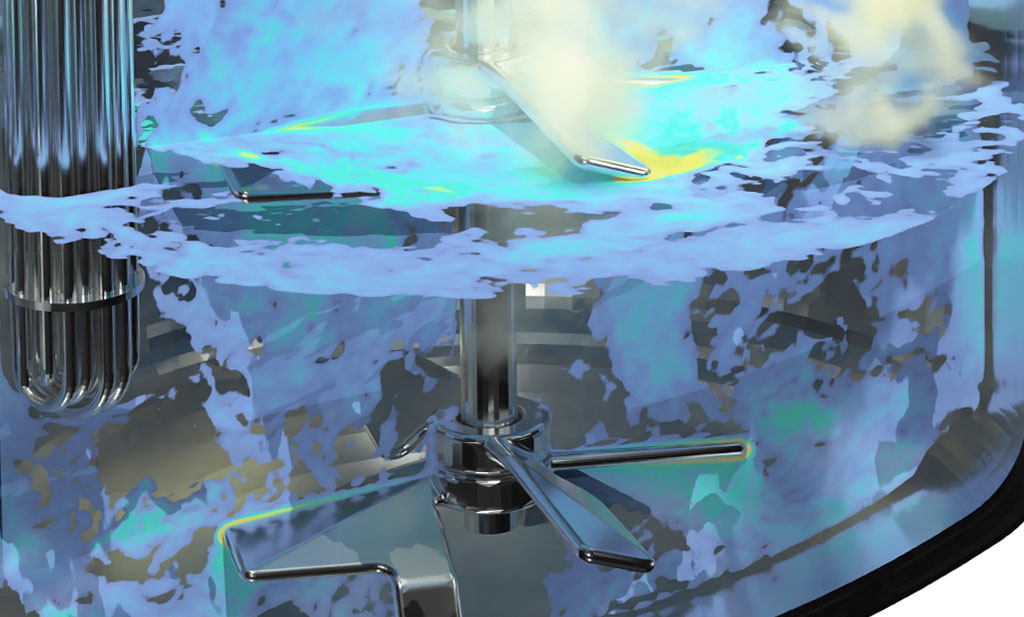

- Performance requirements of an chemical agitated reactor and potentials for operating cost reduction

- New flyer "Process engineering and mechnical calculation possibilities"

- Increased heat transfer with reduced and controlled glass-lining layer thickness

- Thermal Package for glass-lined reactors

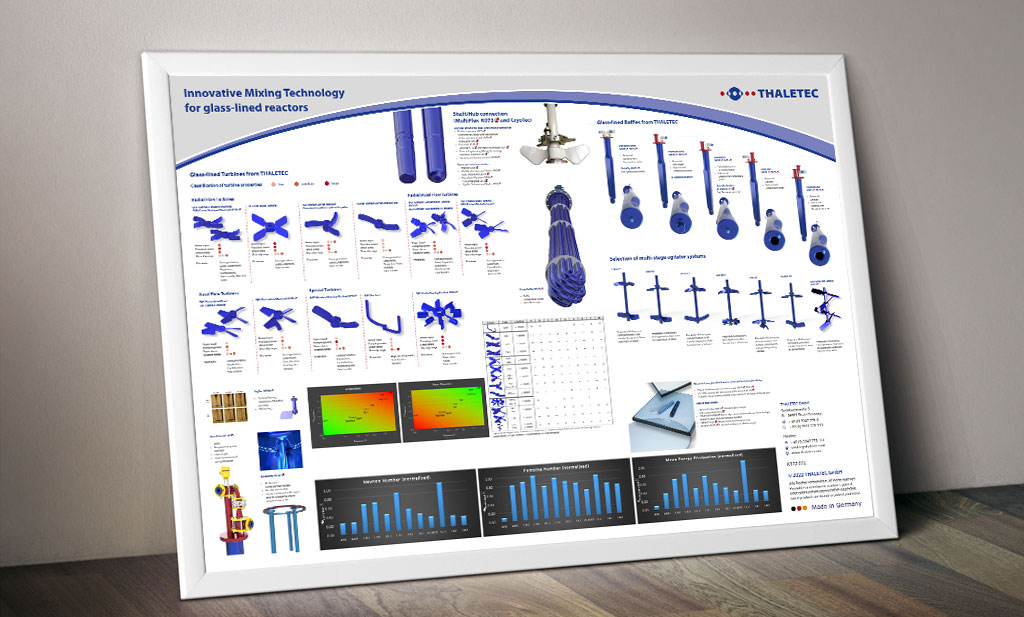

- Poster "Mixing Technology" available

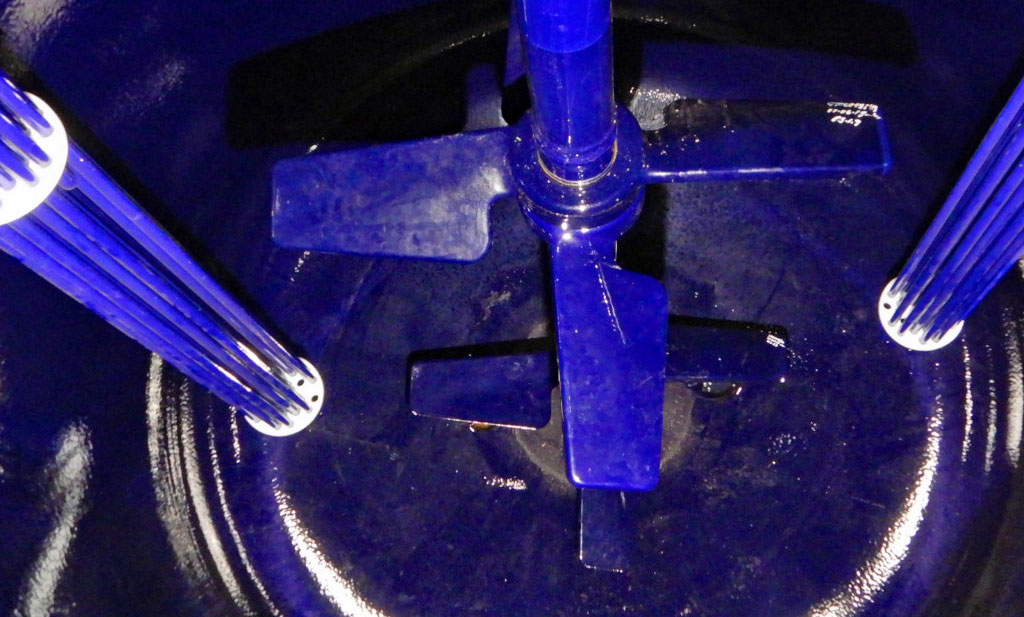

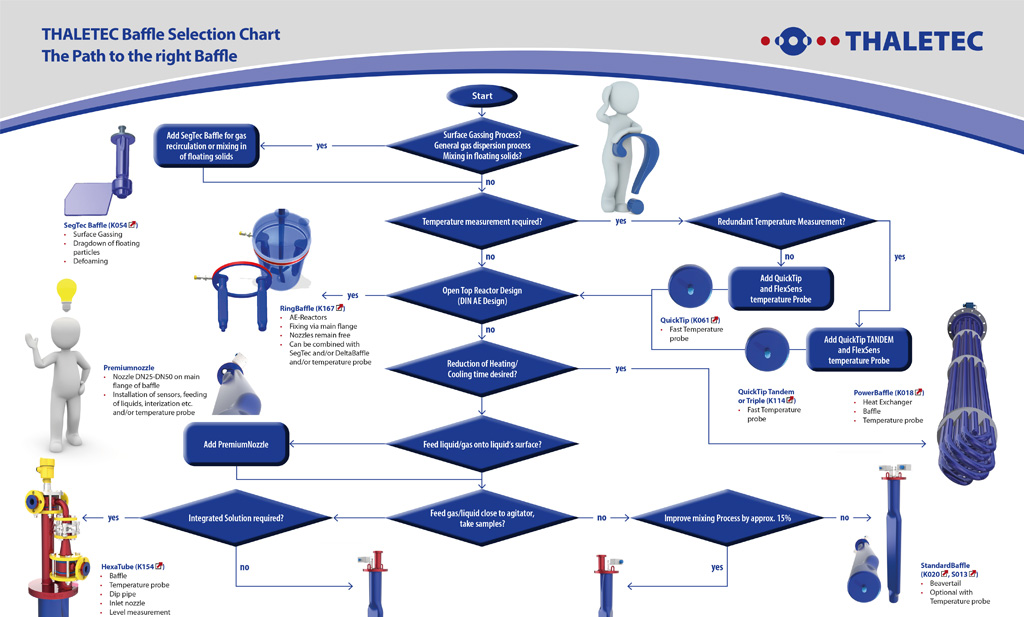

- Selection tool for glass-lined Baffles

- New poster "Heating Technology" available

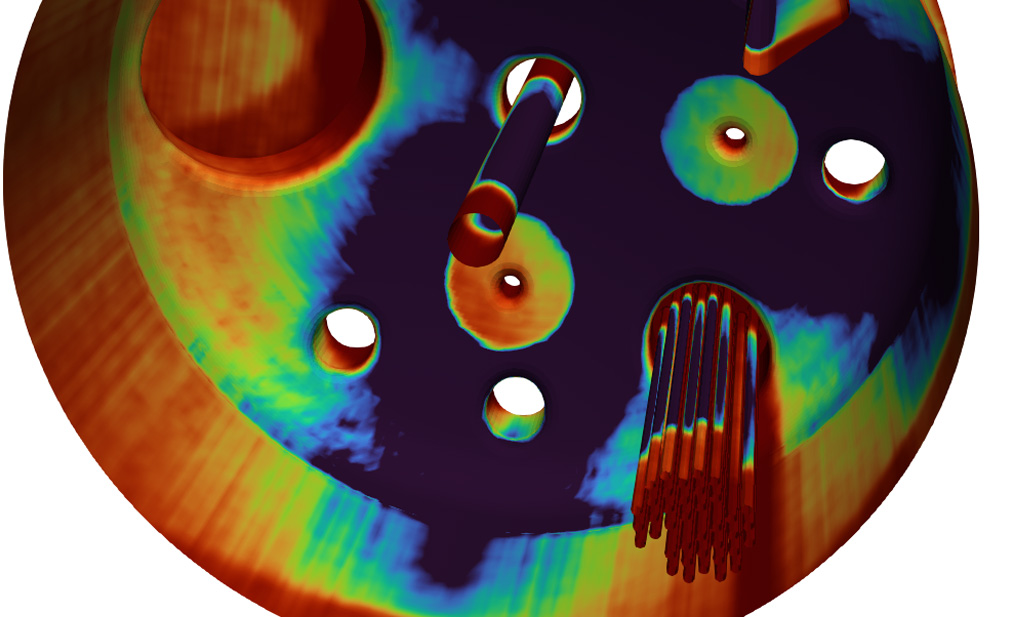

- THALETEC CIPSim – Simulate CIP cleaning

- We seek!

Poster "Mixing Technology"

Different mixing tasks in glass-lined reactors require different agitating systems. It is not easy to keep track of them all. However, the new "Stirring Technology" poster makes it easy for you. It shows everything at a glance! Request a digital copy by e-mail to process@thaletec.com or a printed version under the following link!

We seek!

For a good customer we are looking for one used BE 6.300 and BE 16.000 glass-lined reactor each. The reactors should be designed according to the European Pressure Equipment Directive and have a double jacket. Send an e-mail to process@thaletec.com if you would like to sell such reactors (independent of the original manufacturer) to THALETEC.