Measuring on all levels

With the PowerTubes (Flyer K119), THALETEC offers highly automated glass-lined tubes manufactured in lengths up to 6 m. These tubes are commonly used in heat exchangers for process plants and in power plants and waste incineration plants.

One of the most important applications of glass-lined Powertubes is the construction of heat exchangers which are used in glass-lined reactors instead of the usual baffles: With these Powerbaffles (Flyer K018), heating and cooling times can to some extent be dramatically reduced, which significantly increases the productivity of the plants.

We here present a new application of glass-lined PowerTubes.

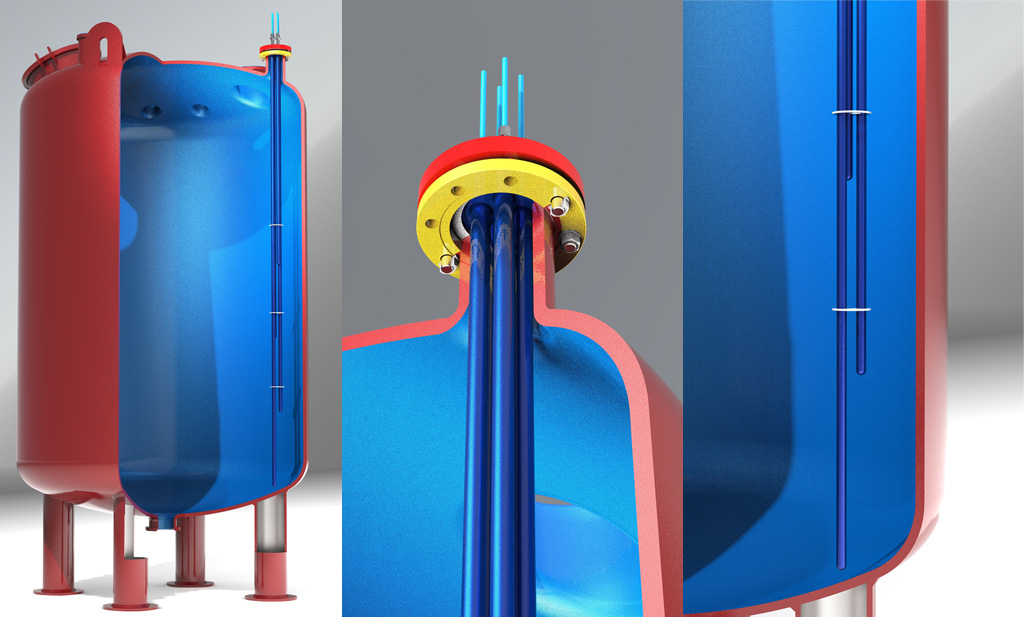

It is often desired to measure the temperature of the medium in large, vertical storage tanks. This may be necessary in order to, for example, control an installed trace heating system, avoid temperature shocks and ensure plant safety. In some cases it is desirable that the temperature stratification in storage tanks should also be known in order to detect safety-critical operating conditions and take appropriate measures if necessary.

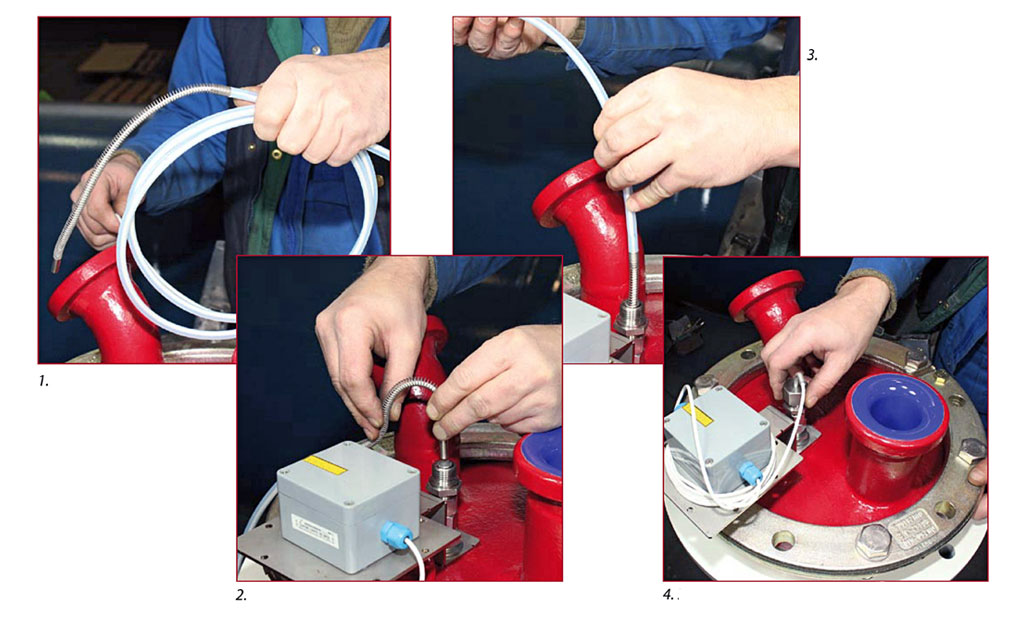

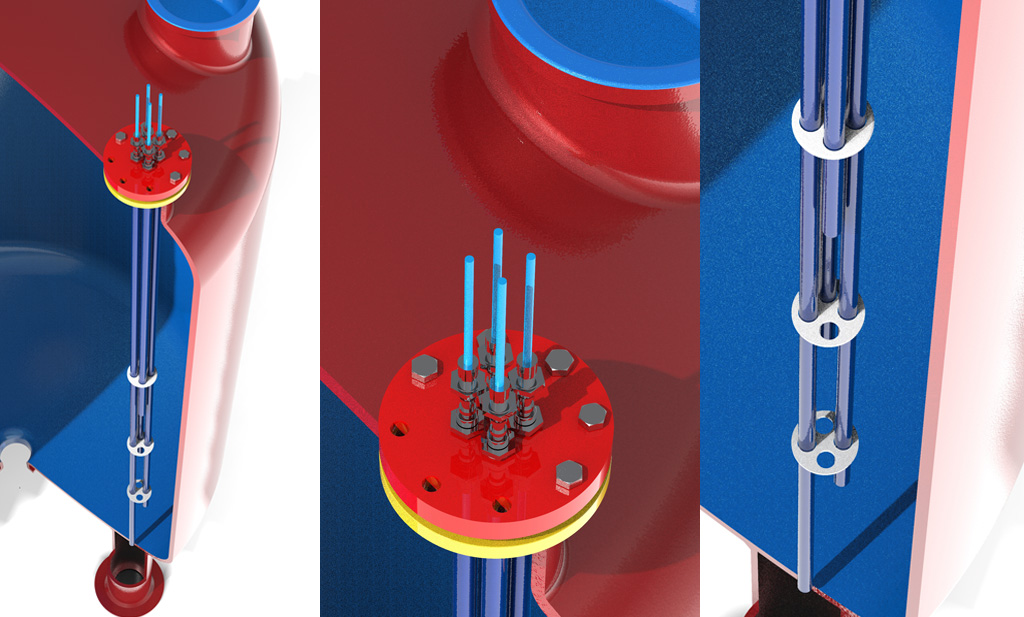

THALETEC has developed a temperature sensor for this application which can be retrofitted. This consists of a flange in which one or more Powertubes of different lengths are installed, depending on the nominal diameter and the measuring task. In each of the tubes respectively there is a temperature sensor in the form of two PT 100 elements in a 4-wire circuit. These sensor elements of the FlexSens type (Flyer K053) can be simply inserted into the tubes of any length.

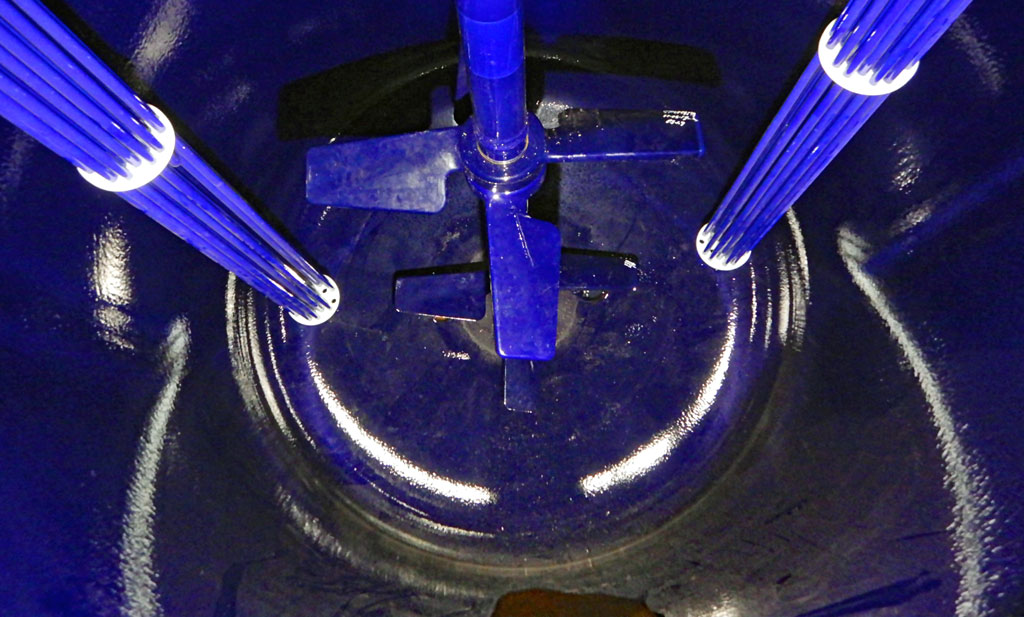

In the specific case, a multilevel temperature sensor was implemented for a 20m³ vertical storage tank.

A DN100 connection piece was available in which a sensor with four independent measuring points on four levels could be installed. As described above, each glass-lined tube contains 2 PT 100s in a 4-wire circuit, which are simply integrated into the process control system via appropriate transmitters.

Of course, the number of measuring points as well as the position of the measuring points can be individually adjusted to the requirements of the installation situation as well as to the requirements of the customer. Contact THALETEC so that we can configure an optimum solution for you.