Introduction

Significant operating costs of an glass-lined reactor (RWA) result from the provision of energy for the drive as well as the conveying and temperature control of the service medium. In the following, the influencing variables and their effects on the above-mentioned topics are examined and finally illustrated by way of example. The inlet and outlet nozzles of the jacket (DM) or the half pipe coil (HRS) as well as the reactor itself serve as system boundaries for the considerations. The considerations apply to liquid service media. The conservative consideration neglects the piping system and thus the associated pressure losses in the pipes, bends, valves, etc., or even the pressure supply to overcome height differences within a plant. For a holistic and individual consideration, the VDI Heat Atlas recommends taking the piping system into account [1].

Operating costs of an agitated reactor

Operating costs of the mixing system

If the operating costs of the drive system of an RWE are considered, the electricity costs and thus the power requirement of the electric motor determine the main costs. The power requirement, in turn, depends on the material properties of the product processed in the apparatus and the stirring system.

P=Ne∙ρ∙N^3∙d_R^5

P... shaft power

Ne... Power Number

ρ... Product density

N... Stirrer speed

dR... Stirrer diameter

If operation in the turbulent range is assumed, the product density has a linear influence on the required power of the drive. The viscosity is negligible and only relevant in the laminar range. In addition, the stirrer speed and, above all, the stirrer diameter have a significant influence on the power requirement, since they are included to the 3rd and 5th power, respectively!

All other aspects, such as the turbine geometry and number as well as the baffle type and number as well as the bottom distance are represented by the dimensionless Newton number, which can be determined experimentally or with the help of CFD (Computerized Fluid Dynamics). Here, THALETEC's know-how can be used to determine or calculate characteristics such as the power requirement, the shaft torque, the specific power input or the critical suspending speed as well as the circulation power and time of the customer-specific agitator technology.

THALETEC offers a wide range of agitators (turbines) to realize individual process conditions. The range covers the entire spectrum from low (low power input, low gravity effect) to high Power number (high power input, high gravity effect).

Operating costs when heating or cooling the vessel contents

For heating or cooling, a service medium must be pumped through the jacket (DM) or half pipe coil (HRS). To provide the service medium, depending on the size of the apparatus, sometimes enormous volume flows (> 200 m³/h) have to be conveyed by industrial/chemical pumps with the lowest possible pressure loss (p < 6 bar).

In principle, the DM has a larger volume flow requirement with a smaller pressure loss compared to the HRS. Water (partly as a gylcol mixture) is often used as a service medium, which must be tempered (cooled or heated to evaporated) depending on the process. Just for heating e.g. 20 m³ of water from 20 to 80 °C the necessary heat quantity is approx. 1,400 kWh!

For the operation of a DM, HRS, upper and lower limit values are recommended with regard to the prevailing flow velocities in order to avoid fouling as well as deposits on the one hand and to avoid excessive pressure losses on the other hand. However, there is a large margin in between to optimize the operating costs at approximately the same cooling or heating capacity.

Calculation of operating costs

THALETEC has the necessary tools and calculation programs to assess the operating costs mentioned. This allows quantitative statements to be made on the various aspects. Since the results are strongly dependent on material parameters and the applied equipment technology, individual calculations are inevitable in each case.

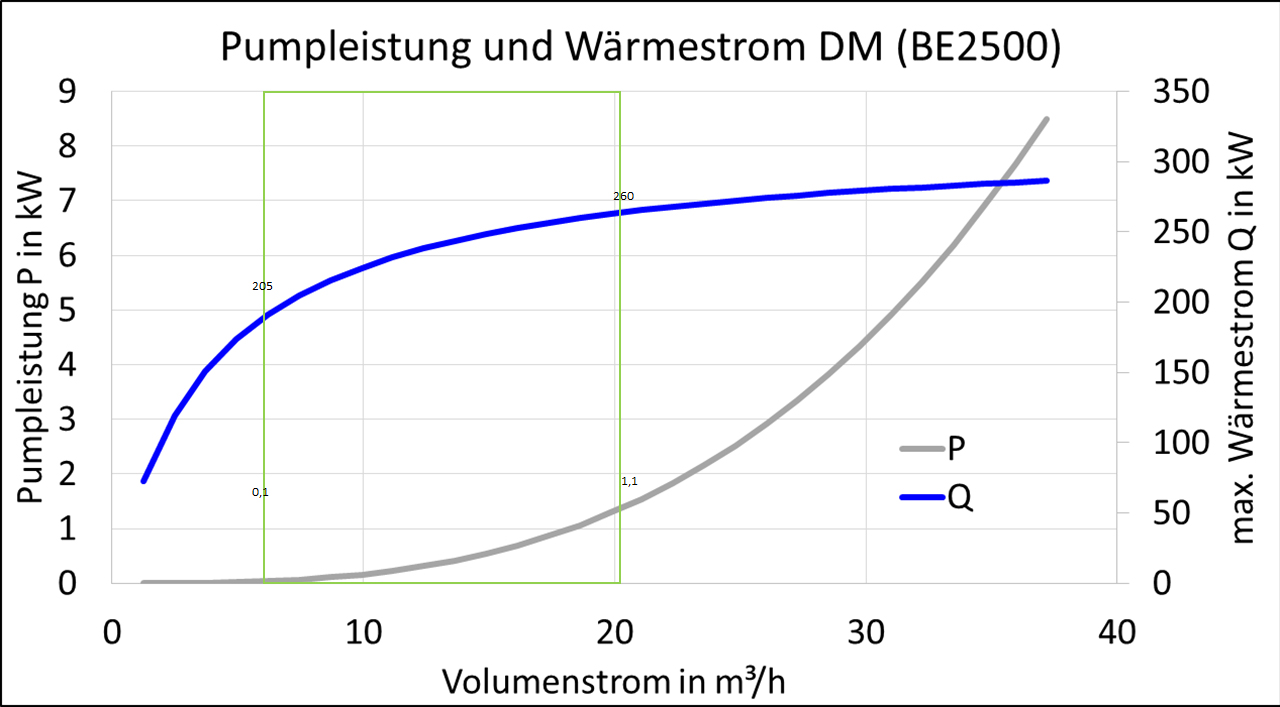

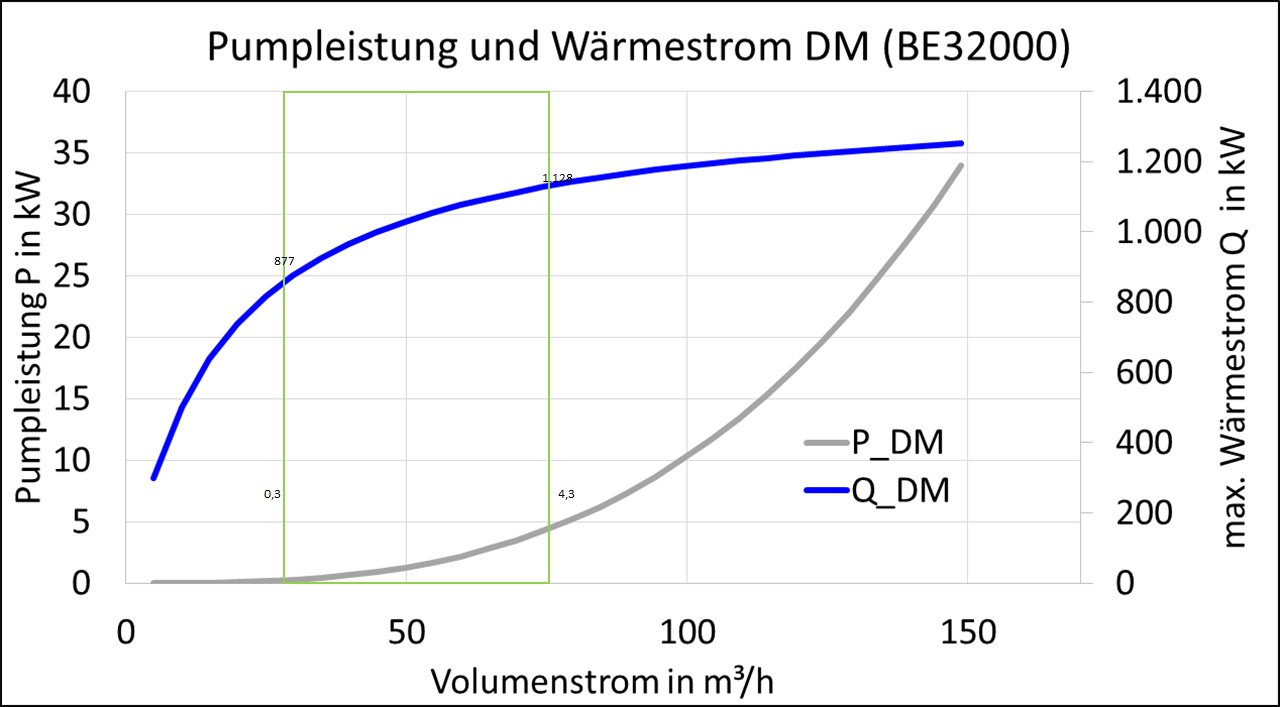

figure 4a and 4b: Required pump capacities for generating the heat flow at the DM of a BE2500 and BE32000 as well as the recommended operating ranges marked in green.

The examples shown above of a BE2500 (CXU turbine) and BE32000 (CXU/TAF turbines), each with a double jacket, are intended to illustrate the possibilities and dimensions (Figure 4). The same process of cooling water (80 to 50 °C) in the product chamber using cooling water (20 °C) as a service medium at an agitator speed of 75 min-1 is considered.

Figure 4 shows the pump power required for pumping the service medium (left axis) and the maximum achievable heat flow between the double jacket and the product, plotted against the volume flow rate of the pump to be pumped.

This example calculation clearly shows that there is great scope for optimization with regard to the necessary pumping capacity for the service medium. If the upper and lower limit values of the recommended operating range are compared, a factor of at least 10 occurs with regard to the pumping capacity, although the max. cooling capacity only shows a difference of approx. 27-28 %!

In addition to the optimization of the heat transfer medium or service side, the agitator technology can of course also be optimized. Here, however, besides the energy demand, especially the process engineering requirements of the stirring task are decisive.

THALETEC offers you the calculation and evaluation of the listed aspects to the operating costs (process(at)thaletec.com).