New highly alkali-resistant technical glass ALKASIST

THALETEC ALKASIST (Flyer K129) is a newly-developed glass lining for processes in which the pH value is (significantly) above 7 for long periods of time.

While standard technical glasses have excellent chemical resistance in highly corrosive acidic processes, these glass linings are less efficient under basic conditions. This is mainly due to the fundamental properties of glass-linings, which also include glass linings.

The resistance of technical glasses is demonstrated by standardized test procedures. These make it possible to compare glass linings from different manufacturers objectively. For proof of alkali resistance, DIN EN ISO 287064 :2011-08 applies. According to this test method, THALETEC ALKASIST has a corrosion rate which is 60% lower than the corrosion rate of a standard technical glass lining. Yet THALETEC ALKASIST also has a corrosion resistance in the acid range (DIN EN SO 28706 2:2011-08 which is within the permissible values according to DIN EN ISO 28721-1:2011-06.

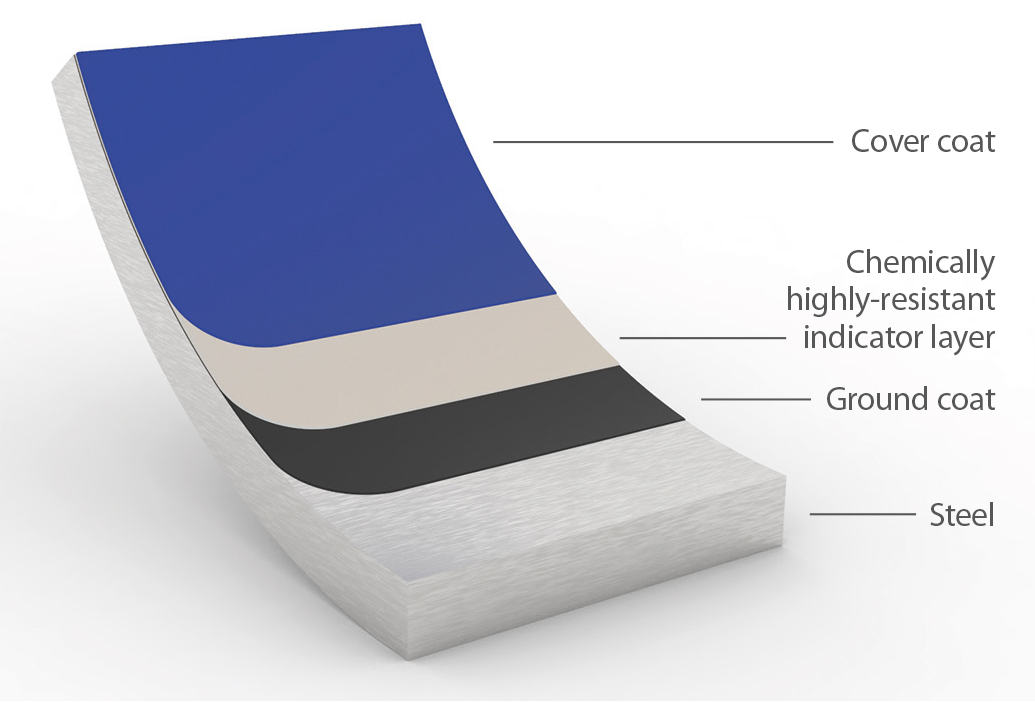

To increase the operational safety of components glass lined with THALETEC ALKASIST and to detect critical glass lining removal early, THALETEC ALKASIST is made in a multilayer process with an embedded, chemically highly-resistant indicator layer. If glass lining is removed during use, the early reaching of end of life can be easily detected visually.

THALETEC ALKASIST is now available for chemically stressed agitated tanks and for components, as well as for columns and storage tanks.

Please get in touch with us so that we can comprehensively advise you.