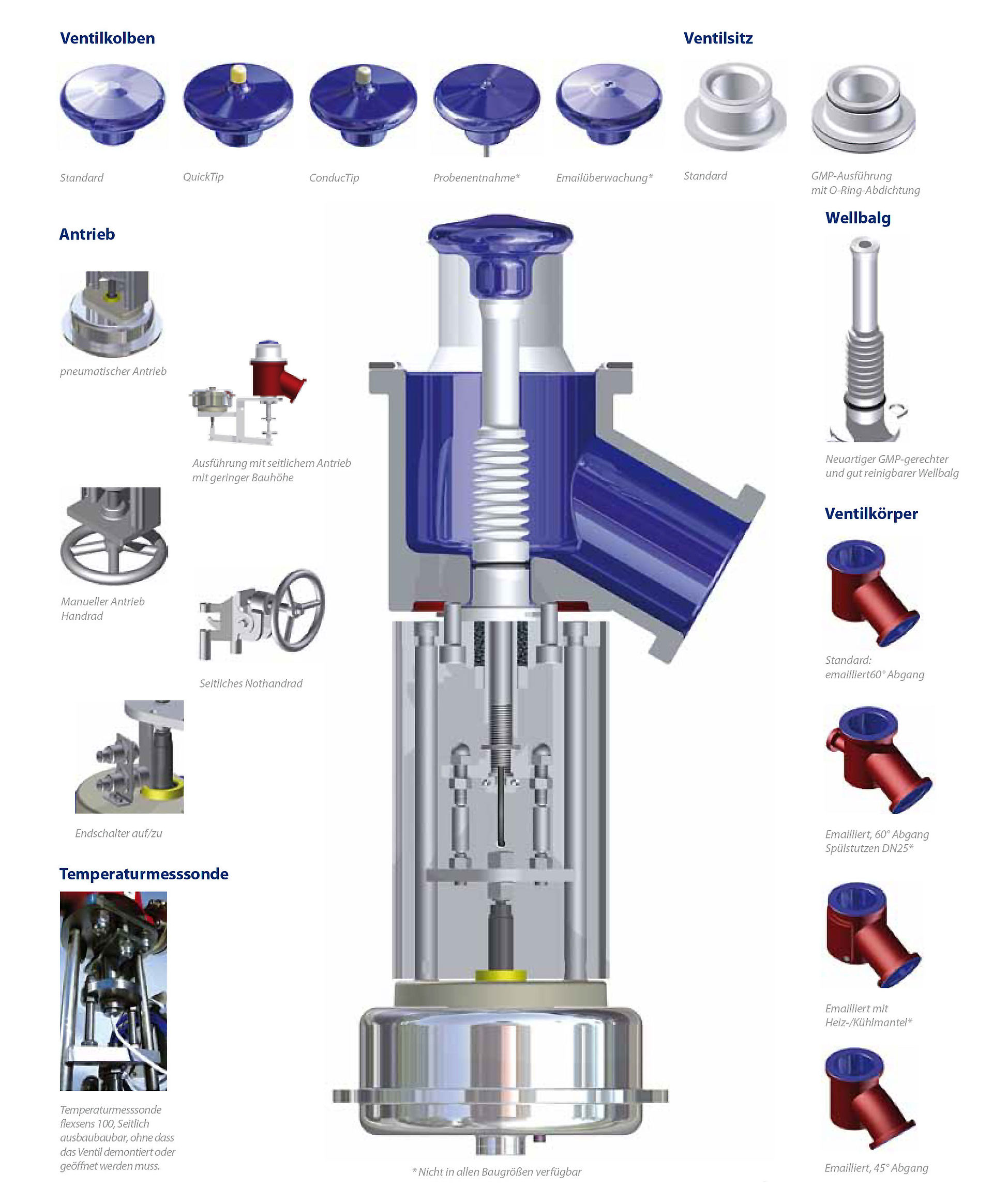

The innovative modular system from THALETEC for glass-lined bottom outlet valves

THALETE C has developed an innovative modular system for glass-lined bottom outlet valves which meets all customer requirements, leaving nothing to be desired. By standardising the individual components our valve programme THALETE C PremiumValve can offer a wide variety of applications. Below we describe some of the options for your application.

Safety

The principal aspect for the bottom outlet valve is the sealing system.

In the case of the THALETEC PremiumValve the glass-lined valve piston forms an hermetic seal against a PTFE fitting. All valve pistons from THALETEC are precisionground on the sealing surfaces to ensure a secure seal in all operating conditions. The THALETEC valve piston is designed in such a way that no product residues can remain "sitting" on the valve piston.

The valve piston is sealed securely against PTFE corrugated bellows. THALETEC's newly developed corrugated bellows have an maximum working life. A high-quality PTFE compound was chosen for the material.

In contrast to conventional folded bellows, the corrugated bellows are less susceptible to material fatigue. The corrugated shape prevents product residues from getting trapped so that the corrugated bellows are not damaged. With the additional safety stuffing box the THALETEC PremiumValve design also complies with the German technical instructions on air quality control (TA Luft).

The pneumatic actuator from THALETEC has a robust stainless steel housing . To increase operational safety the "spring action closure" version was chosen. Should it be necessary for safety reasons for the tank to run empty in the event of a power failure, there is also a "spring action opening" version available on request.

As an option the emergency hand wheel can also be chosen for the pneumatic actuator. In the event of a power failure the spring action of the pneumatic actuator can be overcome and the valve opened manually.

Easy cleaning – GMP, FDA Features

For processes in the pharmaceuticals and fine chemicals industries the valve seat seal to the tank nozzles was also fitted with a soft sealing FEP-coated O-ring.

The THALETEC PremiumValve body is designed in such a way that it is self-draining. An optional cleaning nozzle can be chosen which ensures a perfect clean of the corrugated bellows and the valve interior.

In contrast to conventional folded bellows the THALETEC corrugated bellows are easily cleaned. In addition the corrugated bellows are GMP-compliant with an O-ring forming a seal against the valve body, which has a precisely ground glass lining in the sealing area.

The actuator system of the valve is protected by an easily cleaned stainless steel housing.

Easy to maintain

The valve sizes 80 / 50, 100 / 80 and 150 / 100 (3''/2'', 4''/3'' and 6''/4'') have identical components, which are used in all 3 sizes

e.g.:

- corrugated bellows

- pneumatic actuator

- manual operation

- emergency hand wheel

- open /closed signals

- position controller

- temperature measuring flexsens 100

This reduces the need to store spare parts and also increases the availability of the THALETEC PremiumValve.

Multifunctional

The THALETEC PremiumValve was designed as a modular system so that there is a choice of several functions.

- Temperature measuring Quicktip with temperature sensor flexsens 100

- Earthing point Conductip

- Open /Closed signals

- Enamel monitoring

- Sampling

- CIP cleaning nozzles for corrugated bellows

- The heating/cooling jacket design is available for temperature-sensitive products

- Manual operation

- Pneumatic operation

- Lateral operation

- Emergency hand wheel

Versatile

The modular system of the THALETEC PremiumValve is tailored in such a way that it is just the components which must be replaced or fitted to obtain the required additional functions.

The THALETEC PremiumValve body has a numerous range of options and can be adjusted to meet customer requirements. The standard connections (tank connection /pipe connection) are DN 50 / 32, DN 80 / 50, DN 100 / 80 and DN 150 / 100 (DN 2'' / 1½'', DN 3'' / 2'', DN 4'' / 3'', DN 6'' / 4''). Other connections can be implemented upon request. The PremiumValve is available with an outlet angle of 60° or 45° (optional). A cleaning nozzle DN25 can be chosen as an option to clean the corrugated bellows. There are a number of options available for opening and closing the THALETEC PremiumValve depending on local conditions and customer requests. There is also a hand wheel for manual operation for all valves. The pneumatic actuator is available in an "inline" and a lateral design.

Code-no. / Titel (Link)