Glass-lined cold traps for safety and environmental protection

THALETEC is developing and manufacturing glass-lined cold traps with universal chemical resistance in line with customer requirements.

What are cold traps for?

A cold trap is a device used to separate condensable gas components from a gas stream. Its purpose is, for example, to protect a downstream vacuum pump (from slugging), but it can also be used to reuse solvents and reduce emissions into the atmosphere. If valuable condensable components are present in low concentrations in the gas stream, e.g. solvents, these can be recovered, liquefied and reused (source: Wikipedia).

Cold traps are used in the chemical industry to separate solvents from gas flows. In a heat exchanger, the gas is cooled so that certain gas components condense and are separated in line with the partial pressures.

The condensate is discharged automatically via a filling level control.

In this specific application, the cold trap is connected between the condenser system of a column and a vacuum pump. The cold trap is operated cold. Product carried away with the exhaust gas will solidify on the glass-lined heat exchanger. After distillation, the cold trap is heated and the product can be returned in liquid form to the process. Technical glass lining was specified by the customer's application technology because the condensed product is toxic and acidic.

Glass-lined cold traps for multi-purpose facilities with highest chemical resistance

In many cases, cold traps are made of stainless steel. In some applications, however, stainless steel is not sufficiently chemically resistant. Stainless steels quickly reach their limits, especially when corrosive gases or those containing chloride have to be condensed out. Glass-lined cold traps from THALETEC are available for such critical applications.

Glass-lined cold traps are particularly used in multi-purpose installations because glass-lined steel is highly resistant to most chemical substances. Thus the cold trap does not restrict the universal applicability of the process plant.

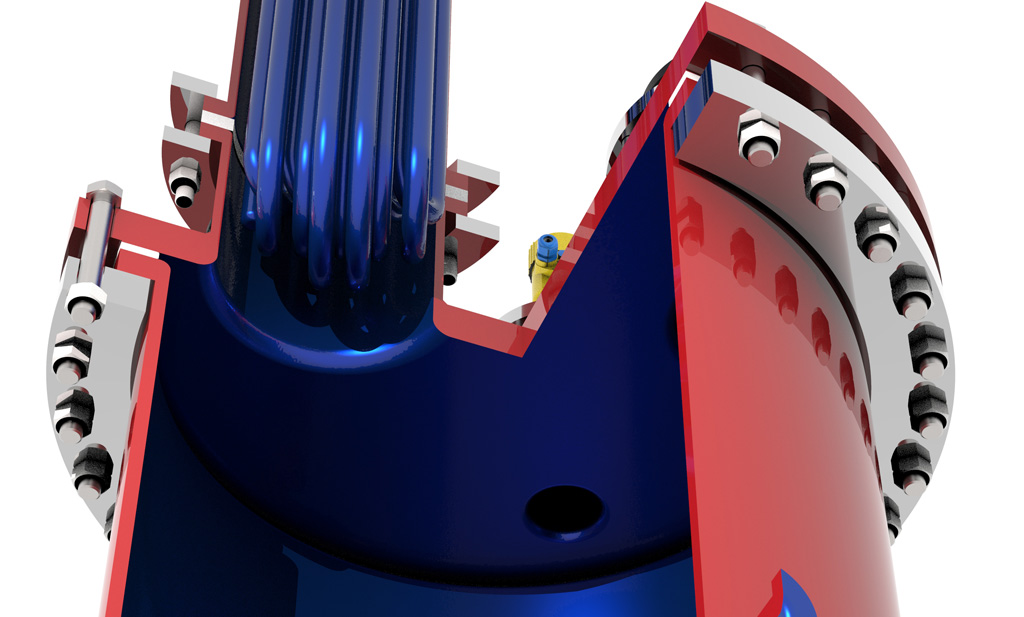

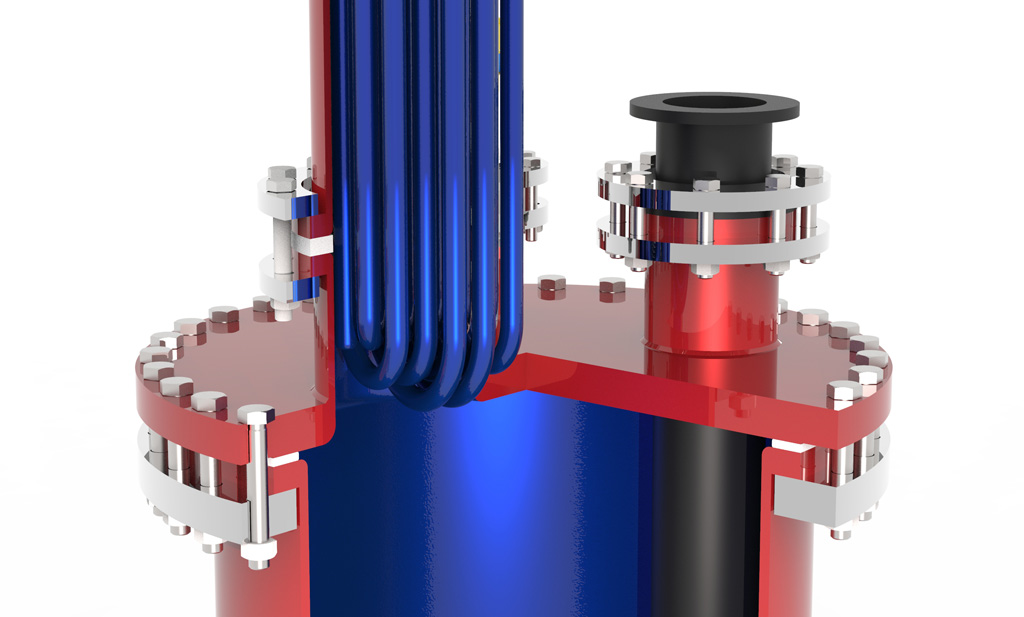

A glass-lined cold trap essentially consists of a collecting vessel on which a glass-lined WTU heat exchanger is placed. The loaded gas flow is introduced into the interior of the collecting vessel via an inlet pipe. The gas then flows through the glass-lined heat exchanger mounted on the collection vessel and leaves the system at the gas outlet nozzle.

The heat exchanger is cooled with brine. On the cold tubes of the heat exchanger, the liquid condenses out of the gas flow and is collected in the collection vessel. After reaching a defined filling level, the collecting vessel is emptied via the bottom outlet nozzle.

If there is a risk of the medium condensed out and collected in the collection container heating up and then evaporating again, the collection container can also be fitted with a jacket. This jacket can then be additionally cooled.

THALETEC designs, develops and manufactures glass-lined cold traps according to the process requirement profile and customer requirements. Get in touch with us so that we can develop and manufacture the optimum technical solution for you as well.

In case you need such a solution, call your local THALETEC sales representative or send us an e-mail to process@thaltec.com.