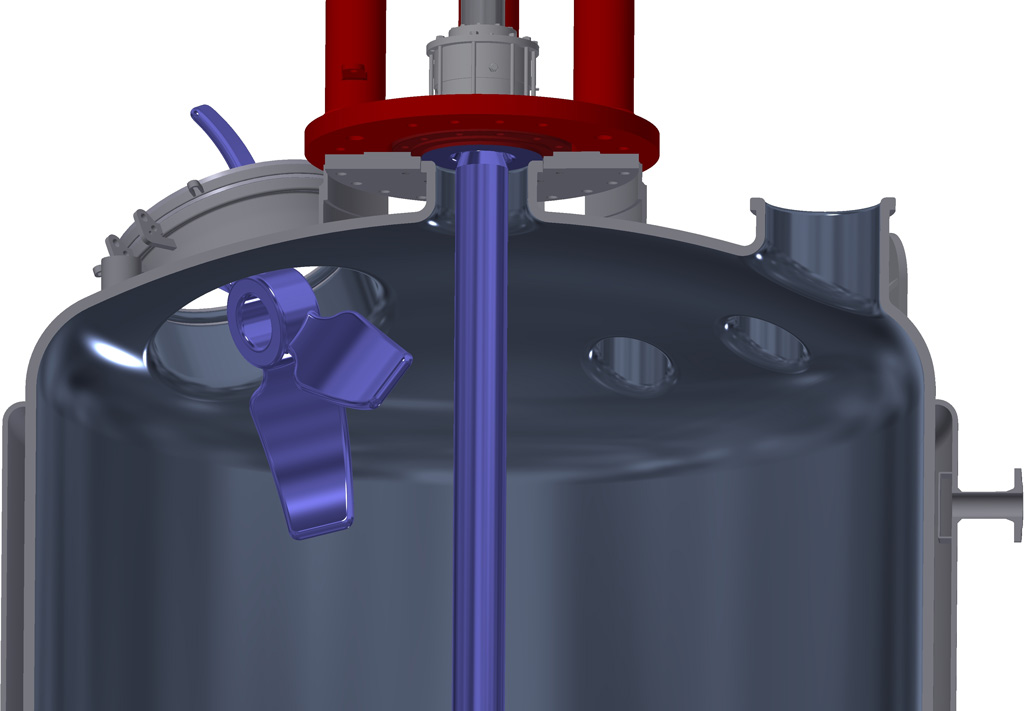

Cost-optimized axial flow turbine TXF

The old acquaintance in a new design

The TXF is a 4-bladed axially-promoting agitating turbine. The new design of the turbine is based on the well-known CXU turbine and is characterised by the fact that the usual 90° between the agitator blades is reduced to 44° to 55°.

The THALETEC turbine, commonly known as TAF, can be found as a single agitator or in a multi-stage system. The trapezoidal design allows a constant velocity distribution over the entire turbine, which is particularly suitable for suspending and homogenising.

The secret lies in the peripheral speed and the area of the agitator. The agitator is very wide at the hub to effectively convert the low peripheral speeds into an axial flow. At the ends, the turbine is very flat to convert the high speeds into a similarly strong axial flow as at the hub.

This is particularly advantageous in multi-stage systems, as the lower agitator receives a uniform volume flow. The uniform axial flow prevents dead zones under the agitator and is therefore particularly attractive for suspension applications.

The new design allows the ever-popular TAF to be manufactured as a one-piece TXF with the same characteristics. Investigations have shown that the power input and the characteristics of the turbine do not change due to the reduced angle of attack of the blades to each other. This is achieved by simultaneously maintaining the height of the blades to each other.

But what are the advantages of that?

- Firstly, despite a different design, you get a turbine with the same characteristics you are already familiar with. Instead of the usual 2-blade TAF you get a TXF turbine.

- Secondly, the assembly of the turbine is greatly simplified. The fitter only has to shrink one hub. This saves time and money. At the same time, 2 blades do not need to be shrunk and repaired separately where there is damage.

- Thirdly, they only have to buy one turbine and not connect 2 blades to one. This simplifies the storage and logistics of the turbine.

- Fourthly, the turbine is becoming more attractive for pharmaceutical applications. The gap between the individually shrunk turbines of the TAF was often too great for the operators. This is now changing.