Fit into the new year – repair and testing of your glass-lined equipment by THALETEC

THALETEC Service above all!

THALETEC has a team of well-trained and experienced service staff. They are well trained to perform all conceivable work on your glass-lined apparatus. For example

- Change and repair of mechanical seals (Flyer K106)

- Changing flange gaskets and manhole gaskets (see catalog S003 and S004)

- Shimming of gaskets

- Measurement of container nozzles for ShimFree intermediate rings (see Flyer K104)

- Performing glass-lining inspections such as high voltage testing and coating thickness testing) (Flyer K169)

- Disassembly and assembly of stirrers of all manufacturers

- Measurement of wall thickness of glass-lined apparatus (Flyer K155)

- Repair of agitator drives

- Help with commissioning and decommissioning of glass-lined equipment

- Repair of bottom outlet valves (Flyer K152)

- Performing glass-lining repairs with enameled repair elements (catalog K093)

- Subsequent installation of tank supports on site – THALETEC PlusPort according to catalog K182

In addition, you can also get all enameled spare parts from THALETEC.

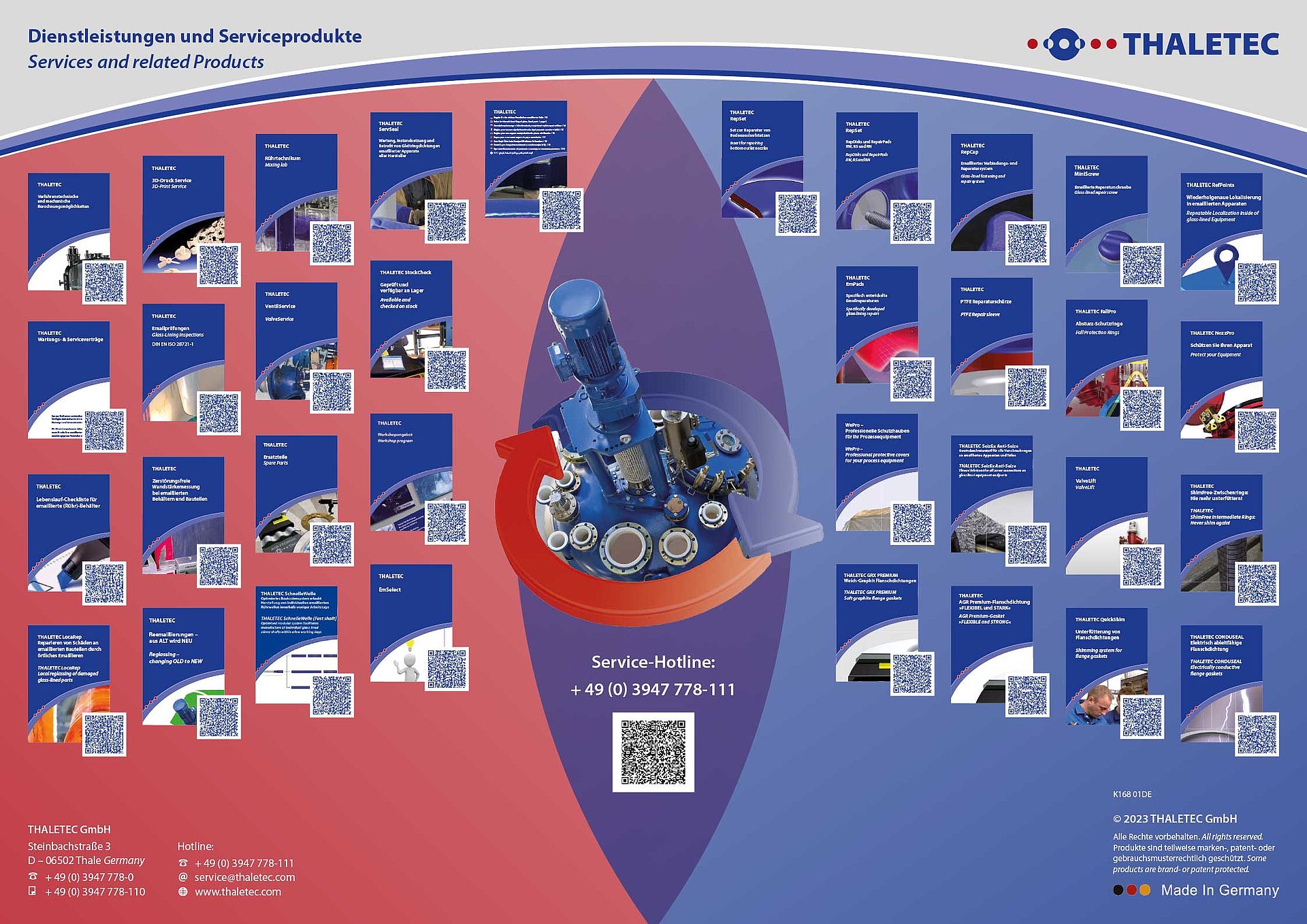

A good overview of service products and services is available in the Poste K168, which you can request by sending an email to process@thaletec.com.

Email checks – what makes sense?

Reasonable and regularly performed tests of the glass-lining of your equipment are

- The high voltage test (Spark test)

- The coating thickness test

- The visual control

In the high-voltage test, a metal brush charged with a test voltage of max. 7 KV is passed over the entire enamel surface in contact with the product. If the enamel coating is damaged, this is indicated by sparking and an acoustic signal. Any damage to the enamel coating that is detected can then be repaired immediately using the THALETEC EmRep repair system (Catalog K093).

The coating thickness test is used to determine the residual coating thickness of the enamel on the apparatus and on installed parts such as agitators and baffles. If the coating thickness locally falls below a specified minimum value, reglassing of the apparatus or replacement of components should be considered. For replacement, THALETEC offers the supply of glass lined spare parts for apparatus of all manufacturers. Likewise, THALETEC carries out reglassing of components and apparatus of all manufacturers (Flyer K060).

Visual inspection requires a great deal of experience and expertise. THALETEC service staff are trained accordingly and are able to visually assess potentially endangered enamel surfaces and suggest measures to you.

You see: THALETEC helps you to bring your glass lined equipment fit into the new year. Please contact our service department (e-mail. Service@thaletec.com) or call: +49 (0) 3947 778 250!