THALETEC Thermosist – Let the Heat run free!

Motivation

Technical glass-linings combine unique properties such as high acid resistance and very good cleanability. Combined with a cost-effective base material (“carbon steel”), the composite material steel/enamel also represents a very good economic and ecological solution compared to other materials with a high chemical resistance. If glass is considered from a purely physical point of view, the material property of thermal conductivity is low, so that the coating and the layer thickness are the bottleneck for heat transfer. However, a small increase in thermal conductivity results in a significant improvement in heat transfer, which benefits many thermal processes in the chemical and pharmaceutical industries. Increased heat flow results in shorter batch times and consequently an increase in productivity and a reduction in operating costs.

Increasing thermal conductivity with ceramic crystals

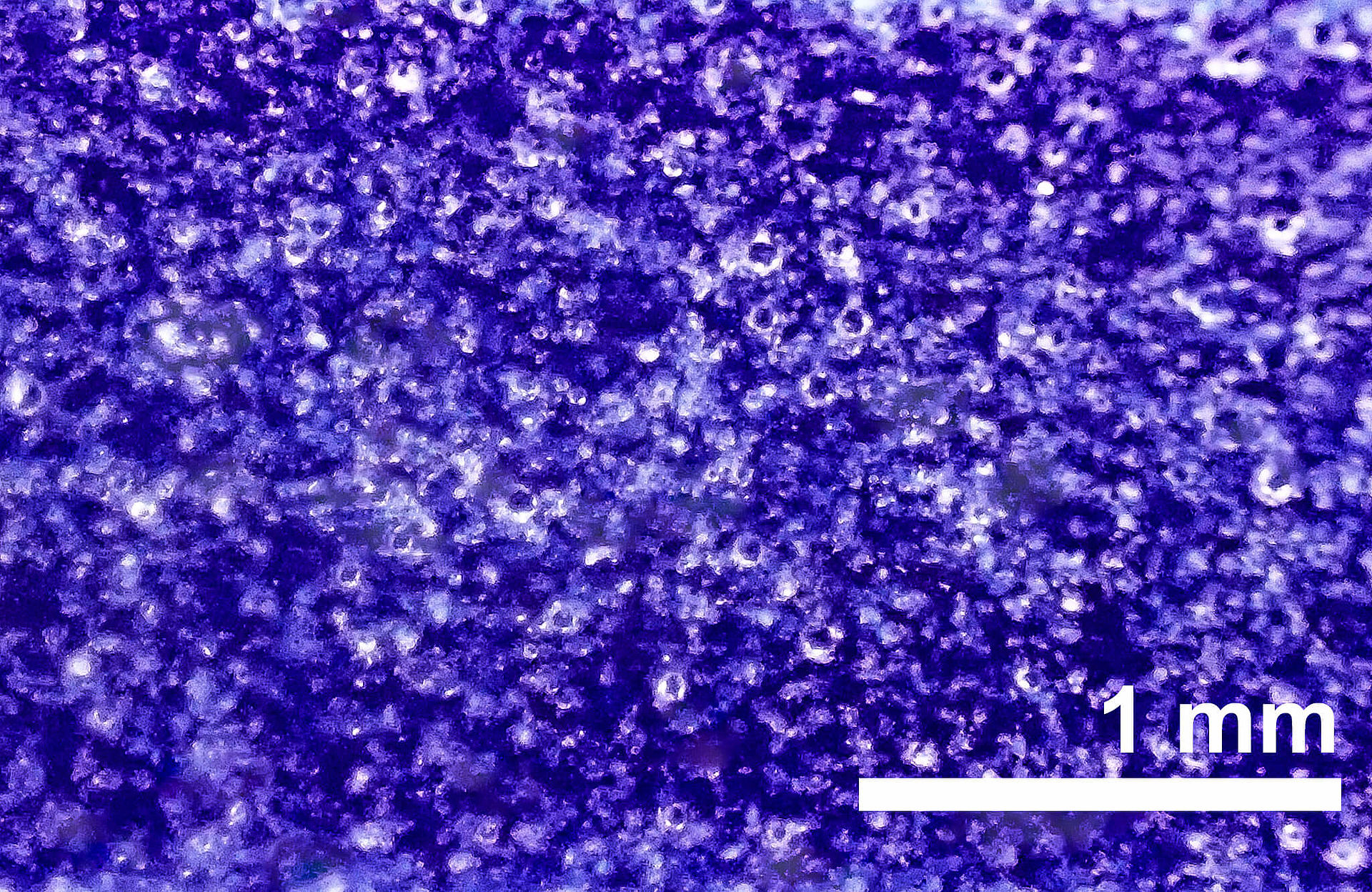

THALETEC Thermosist is based on a conventional technical glass-lining. It therefore has the same properties in terms of chemical resistance and meets all the required standards. To achieve a higher thermal conductivity, THALETEC Thermosist is doped with highly thermally conductive ceramic crystals, which have similar properties to the glass-lining itself. Aspects such as particle shape, size and concentration are decisive factors to produce a glass-lining with a high quality. A uniform particle distribution ensures increased thermal conductivity over the entire layer thickness (Figure 1).

Figure 1: Micrograph of THALETEC Thermosist. The uniformly distributed thermally conductive crystals embedded in the glass matrix are clearly visible

Measurements at an external laboratory confirm that the thermal conductivity of THALETEC Thermosist is +40 % higher than that of conventional glass-linings. With otherwise comparable properties of the glass-lining, this represents a decisive step towards more efficient operation of glass-lined equipment! THALETEC Thermosist has a medium blue colour with a matt glossy appearance.

Application example of a BE16000

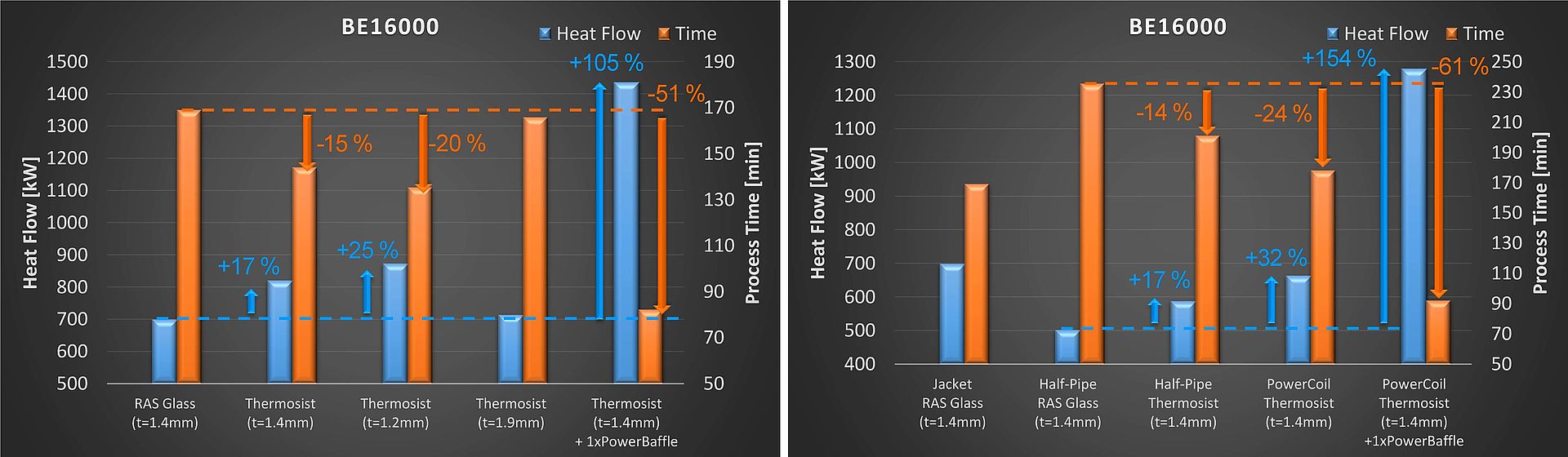

The thermal conductivity of the glass-lining is only one, but decisive, part of the heat transfer coefficient of the composite material. The following calculation examples based on a glass-lined reactor (BE16000) are intended to illustrate the advantages of THALETEC Thermosist. Variants of the BE16000 with jacket and half-pipe coil are compared with each other (Figure 2). They all have the same process step in common, which is a cooling process of water at nominal volume. The product is cooled from 80 °C to 30 °C using cooling water (20 °C). The mixing technology is also the same in all cases. Only the glass-lining used and the cooling designs vary.

The comparative calculations clearly show the advantage of the THALETEC Thermosist. With the same layer thickness, the heat flow is increased by +17 % and the process time is reduced by -15 %. If attention is also paid to a thin layer thickness of the glass-lining, which is still within the standard range (DIN-EN-ISO 28721-1), an increase in heat flow of +25 % can be achieved compared to a conventional glass-lining - the process time is reduced by -20 %.

A further increase in the efficiency of a glass-lined reactor can be achieved using an optimized half-pipe coil, the so-called PowerCoil (K174), and/or a PowerBaffle (K018). The PowerBaffle combines the functions of a baffle, heat exchanger and temperature measuring system.

Summary

THALETEC Thermosist provides the user with a further opportunity to increase productivity while reducing operating costs (shorter process times). Thermally relevant surfaces can be glass-lined with THALETEC Thermosist during new manufacturing or re-glassing Are you interested in the THALETEC Thermosist product brochure or do you need a thermal calculation? Simply contact us by e-mail at process@thaletec.com.