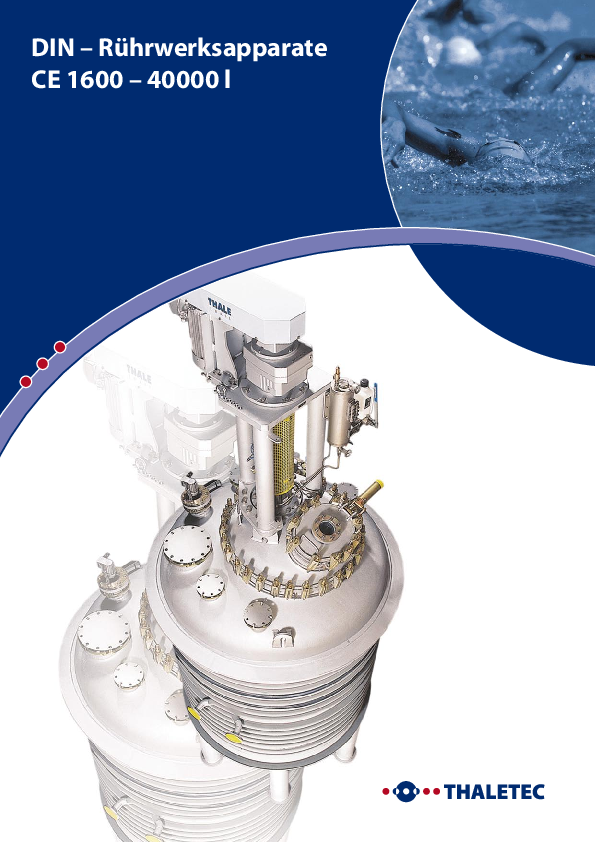

Baffles are flow disrupting elements in stirring tanks. They impede the co-rotation caused by the centrilized flow from the agitator's movement agitator inside the reactor (see the link of a reinforced and not reinforced reactors below). Baffles are installed in one of more nozzles of the top of the glass lined reactor.

THALETEC offers a wide range of baffles. The innovative solutions starten by the standardized baffles up to the multi functional PremiumTube.

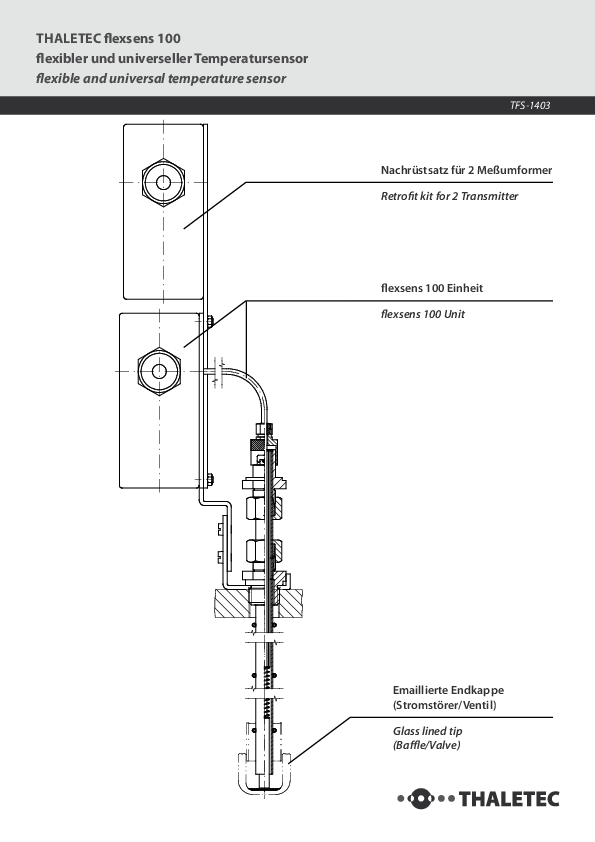

Der THALETEC PremiumBaffle you the possibility, to have multiple usages of the reactor's baffle nozzle and thereby increase the flexibility of your reactor. Baffle, temperature measurement and an additional support in one single component.

The THALETEC Delta Baffle is an innovative and highly effective design for optimal baffling effect in your glass lined reactor. The triangular form of the baffle enables two different mountings and corresponding different baffling effects. In one mounting position the Delta Baffle is particularly suitable for hydro-abrasive processes.

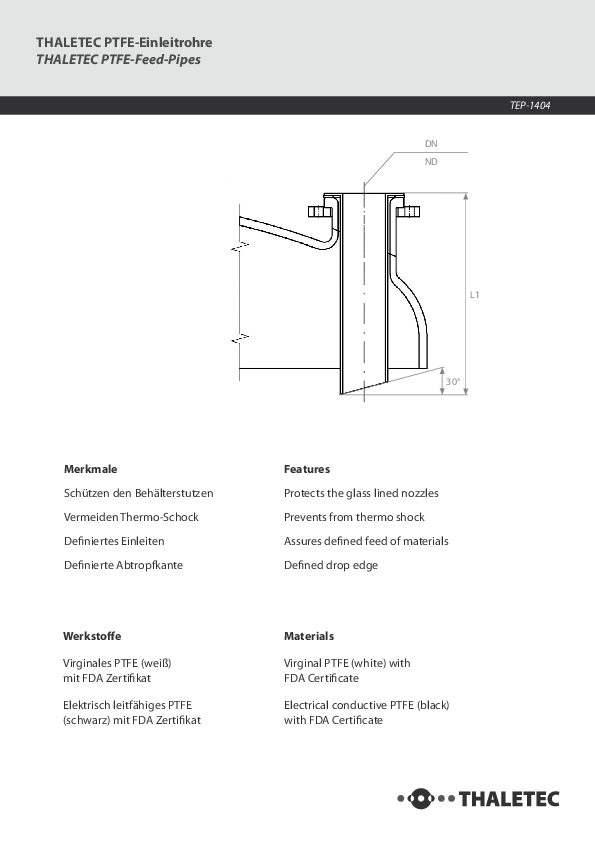

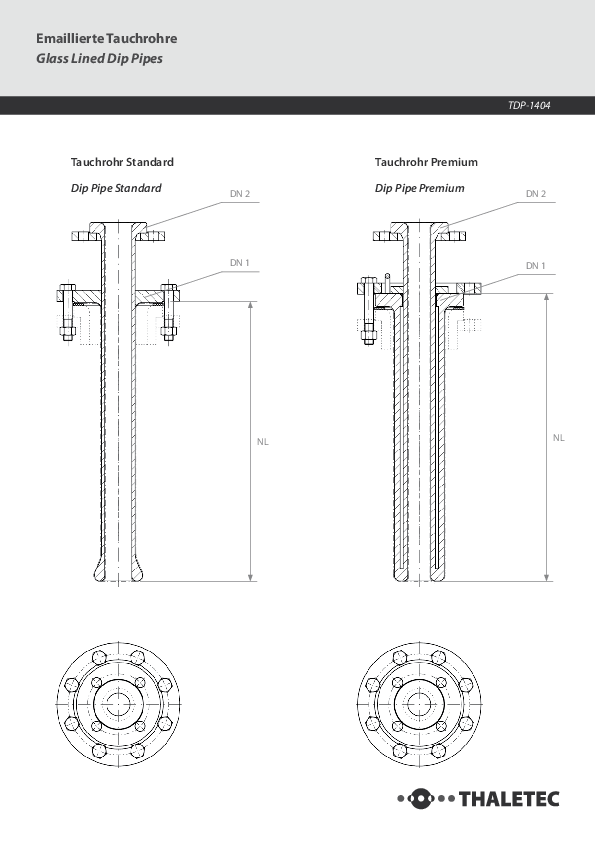

The THALETEC MultiTube enables you to use the baffle nozzle for multiple functions and thereby increase the flexibility of your reactor. Baffle, temperature measurement and dip pipe aggregated all in one component.

The THALETEC PremiumTube is a combination from the THALETEC MultiTube and PremiumBaffle. Additionally to PremiumBaffle the PremiumTube has an integrated dip pipe and offers you therefore 5 functions in one component.

is a quantum leap the the process leadership, improves the efficiency of your manufacturing process and increases the flexibility of your reactors. The PowerBaffle replaces or complements a conventinal baffle and significantly improves the heat transfer of your reactor. Shorter heating and cooling cycles through significantly increased heat transfer capacity.All components can be optionally equiped with the THALETEC flexSens temperature measuring system.