THALETEC reglasses everything – even equipment from TENEZ (Czech Republic)

THALETEC has a long tradition of reglassing equipment from other manufacturers. The advantage for the customer is that by reglassing, even old and defective equipment and components can be brought up to a technically up-to-date standard at low cost. The special types of glass lining such as the electrically conductive Condusist (Flyer K098) or the particularly wear-resistant Abrisist (Flyer K028) are also available for reglassing.

Up until now, the reglassing of equipment originally manufactured by the Czech company TENEZ has sometimes been difficult. The materials used and the welding technology were not fully compatible with THALETEC's new high-performance glass linings.

After intensive optimisation of the glass lining application process and the firing parameters, it is now possible to reglass TENEZ equipment and components safely and with the highest quality using THALETEC glass linings.

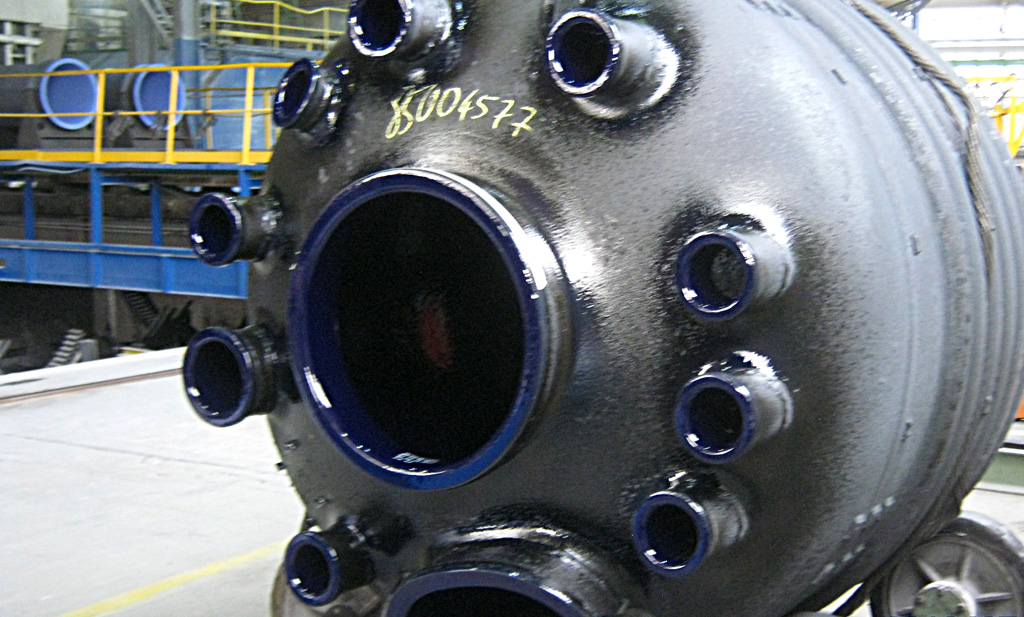

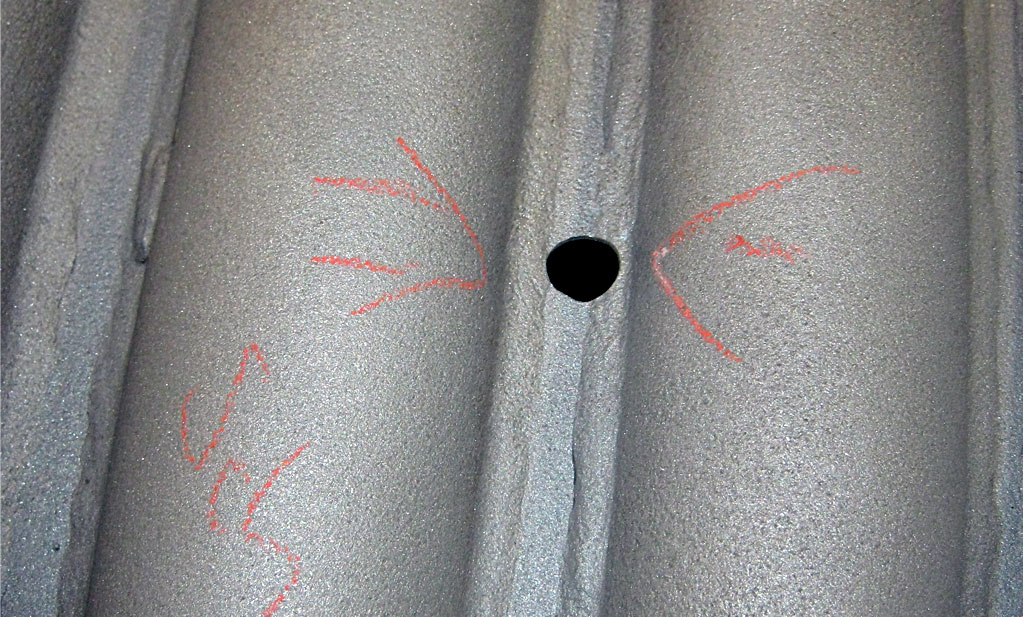

One of the first items of equipment manufactured by TENEZ and successfully repaired and reglassed by THALETEC is a CE 2,500 l with half-pipe coils, built by TENEZ in 2011. The equipment exhibited breakthrough damage in the cylindrical area, which was initially closed. Reglassing was carried out with the chemically highly-resistant RAS glass.

Do you also use TENEZ equipment and components that urgently need to be reglassed or otherwise reworked? Talk to us - we will find a solution!