THALETEC QuickShim - Systematic shimming

THALETEC QuickShim allows flange unevenness and flange distortions to be levelled out quickly, easily and safely.

Due to the production process, the flanges of glass-lined components may show deformations resulting from the burning process. Corresponding permissible tolerances are specified in DIN 28005, 28006 and 28007.

Depending on the diameter of the flange and on the type of equipment, divergences in evenness of up to 7 mm may be permitted.

This unevenness must be levelled out in order to ensure the tightness of the tank flange at pressures up to 10 bar and over. The levelling out of flange unevenness has hitherto often been performed by shimming the flange gaskets with wedge-shaped inserts which are cut to size and an exact fit. This involves the tailored inserts being placed inside the sleeve.

Understandably, work of this kind can only be performed by highly experienced staff and is very time-consuming.

To significantly accelerate the process of shimming flange gaskets to level out flange deformations resulting from the production process, THALETEC is offering a shimming material based on synthetic resin for spraying plus the requisite flat gaskets.

THALETEC QuickShim shimming system

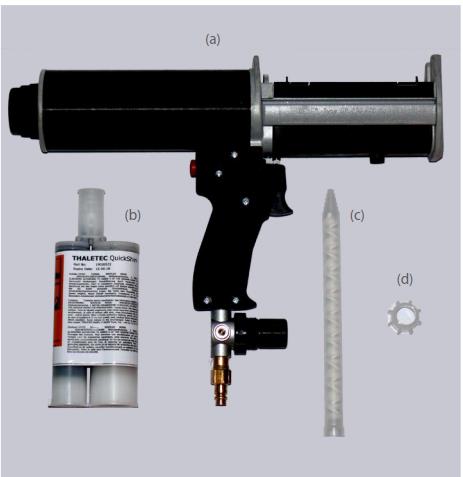

QuickShim shimming material (Flyer K105) is a 2-component resin-based system possessing good processability under various environmental conditions, a sufficiently long processing time, optimum temperature stability and durability.

With the aid of a compressed air-powered cartridge gun, THALETEC QuickShim, delivered in a double cartridge, is injected into the sealing sleeve.

The double cartridge mixing tube ensures the homogeneous mixing of the two components. The tube is fitted with a union nut so that a cartridge once opened can be easily closed again - without mixing the two components in the connection head when unscrewing the mixing tube and thereby clogging it.

We also show the procedure in a video 1

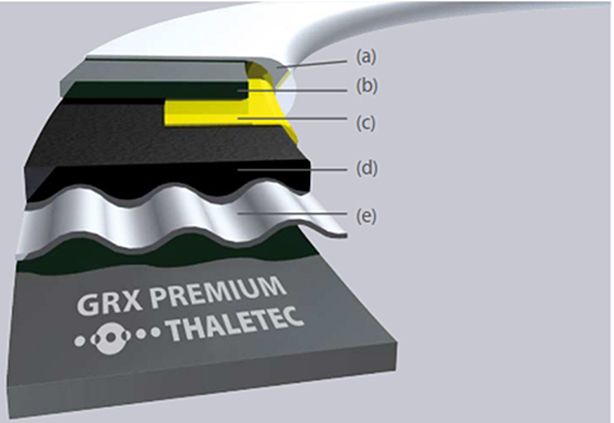

THALETEC Flat gaskets for shimming

The protective cover made of PTFE foil ensures that the paste-like THALETEC QuickShim shimming material which is later inserted into the sealing sleeve cannot damage the actual sealing sleeve after curing. You can find flat gaskets suitable for use with QuickShim and a protective film (Position ‘c’ in Illustration 13) in Flyers K025 (AGR premium), K099 (GRX Premium) and as an electrically conductive variant in Flyer K100.