Limits of tantalum as a repair material for glass-lined process equipment

Practical experience shows it again and again

Tantalum repairs to glass-lined equipment have a limited lifespan, even if checked and monitored regularly. Where does it come from? And what can you do about it? This article gives an insight and shows solutions.

Tantalum is a "universally chemically resistant material"; at least this is the assumption. In reality, tantalum is by far not "universally" resistant and only rudimentarily covers the range of application of glass-lined process equipment [1]:

Because tantalum is resistant to chemical substances of all kinds, the material is often compared with precious metals. Thermodynamically, however, tantalum is a base metal that can form stable compounds with a wide variety of elements. In air, tantalum forms a very dense oxide layer (Ta2O5), which prevents chemical attack on the base material. This oxide layer makes tantalum so corrosion resistant.

However, if a base material such as tantalum comes into contact with a noble material such as platinum, chemical reactions occur very quickly. For this reason, consider the behavior of tantalum in relation to other construction materials, especially at high operating temperatures.

Even at room temperature, tantalum is not resistant to the following inorganic substances: Concentrated sulphuric acid, nitric acid, fluorine, hydrogen fluoride, hydrofluoric acid, sodium peroxide and acid solutions containing fluoride ions. Also alkaline solutions and molten sodium hydroxide as well as potassium hydroxide attack tantalum. If tantalum is attacked, it absorbs hydrogen into its metal lattice and becomes brittle. As the temperature increases, the corrosion resistance of tantalum decreases slowly.

Critical for the resistance of tantalum is that its corrosion resistance can deteriorate if it comes into contact with solution mixtures, even if it is resistant to the individual components.

Thermal expansion of tantalum

The linear coefficient of thermal expansion of tantalum is about 6.4*10-6 m/K and thus about half of the glass-lined steel. If components with tantalum repairs are exposed to changing temperatures in a chemical process, small relative movements occur between the tantalum repair element and the glass-lined component. In the long run, such relative displacements can lead to leakage at the seal between tantalum and the glass-lined component.

Strength of tantalum

The yield strength of tantalum is about 120-200 MPa and thus only about 40-70% of the steel sheet used for the construction of glass-lined process equipment (usually P275 NH). The tensile strength of tantalum is between 225-280 MPa and thus also significantly lower than that of the boiler plate (390-510 MPa) [2]. Tantalum screw joints are therefore hardly resilient; a slight coating of tantalum screws immediately leads to a loss of preload, permanent deformation of the screw thread and a permanent loss of sealing pressure.

Deformability of tantalum

Tantalum and tantalum alloys are very malleable, which is favorable for adapting tantalum repair elements to the shape of the container to be repaired. The high ductility and "good formability" make the use of tantalum for components subject to force, such as screws and nuts, problematic. For example, tantalum screws, which are used to fasten tantalum sheets, must only be tightened with a very low torque, otherwise they will lengthen and be damaged.

Tantalum repairs and vacuum

Especially for large-area repairs with tantalum plates or tantalum sheets inside an glass-lined reactor, the limits of what is feasible are quickly reached. This is particularly the case when a vacuum is present in the apparatus under operating conditions or during emptying. Since atmospheric pressure prevails behind the tantalum plate, the plate will bulge out.

The sheet metal deforms in accordance with the loads resulting from the sealing pressure and the external vacuum: The edge of the sheet metal bulges upwards, against the direction of force of the sealing pressure. The inside of the sheet is "sucked in" by the vacuum. And bulges accordingly towards the inside of the container. At the same time, a relative displacement of the sheet can occur in the area of the bolt connections, which can lead to a gradual reduction in the bolt prestressing force and thus the sealing pressure.

The consequence of this stress and the resulting deformations is a leakage and thus the failure of the repair.

The solution: Glass-lined repair elements

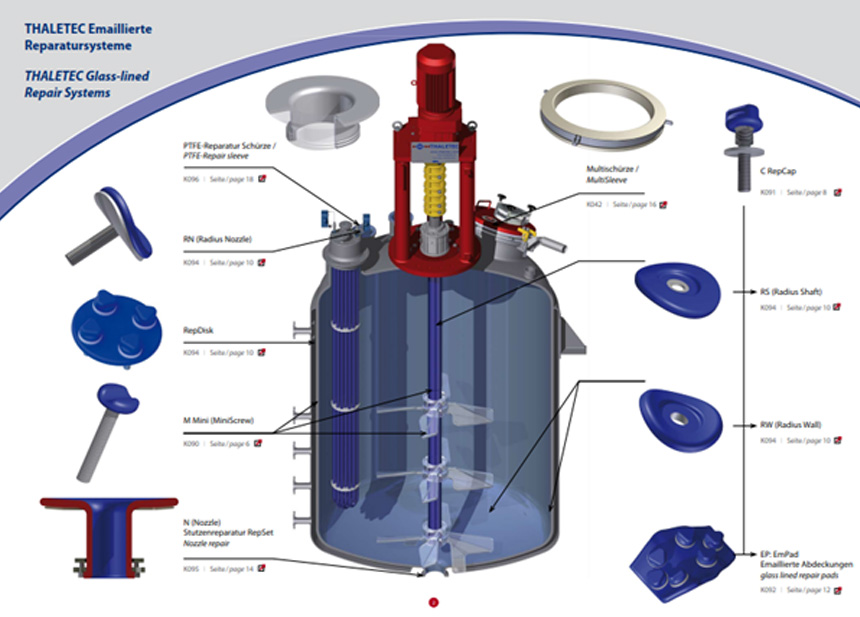

THALETEC EmRep (Flyer K097) comprises a series of glass-lined elements for the repair of glass-lined reactors, tanks and components.

The offer ranges from glass-lined repair elements for small damages, for which individual tantalum screws were previously used, to 3D printed glass-lined EmPads up to dimensions of 700x600 mm for repairing even the largest damages.

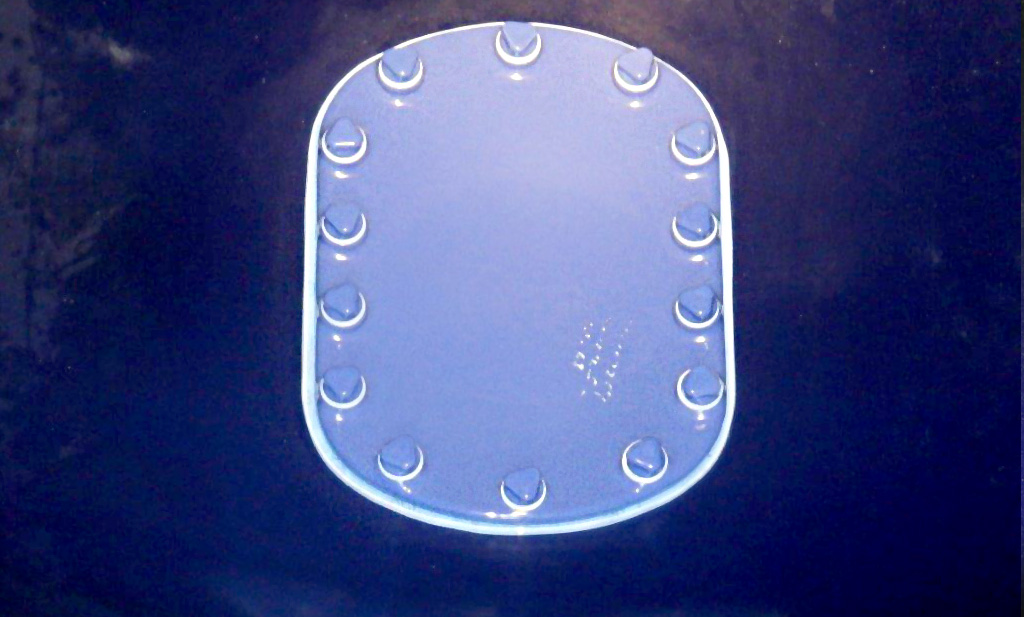

Figure 3 shows such a large EmPad: The repair element has the dimensions 700x400 mm and was installed in a 20,000 l agitator vessel of a third-party manufacturer.

Since EmPads are made of glass-lined steel, they have the same properties as all other glass-lined components. They are mechanically stable, particularly wear-resistant with THALETEC Abrisist glass-lined, pressure- and vacuum-proof connected to the container and chemically universally resistant. EmPads represent a safe and durable repair method even under critical production conditions, which has also been proven in customer trials (example here).

Glass-lined repair elements have been used successfully for many years. If you have a damaged apparatus or a damaged part and do not know how to carry out the repair, please contact us! We will be glad to help you.

In our workshops, which we hold regularly, you will learn more about the glass-lined repair options. Thus we continuously train the employees of our customers in the areas of maintenance. Information on the current training offers can be found in Flyer K108.

Literature

[1] https://www.plansee.com/de/werkstoffe/tantal.html

[2] http://www.metalcor.de/sinterlegierungen/tantal/, https://eserviceepc.sz.salzgitter-ag.de/lieferprogramm(bD1kZSZjPTAxMQ==)/main.htm?gv_product=WBT&gv_quality_group=DIN%20EN%2010028-3&gv_quality=P275NH&gv_pricing=&gv_pricing_version=&inside_ep=&gv_version=5&gv_basismaterial= ).