Use the THALETEC Know how to solve your mixing tasks. Customized and optimized mixing systems with the help of the testing expertise of the THALETEC Mixing college. THALETEC mixing college has different pressure free tank systems e.g. open glas tanks with arched bottoms (300 and 400 mm diameter), Tanks with flat bottoms etc.

The test bench enables you to understand your mixing process in a small scale with the help of model liquids. This helps you for instance to scale up the production scale. We measure the agitator performance and shaft torque with different model liquids and we can replicate the working conditions of the real case. Mixing time and suspension tests are also possible.

Nitrogen aereation or air and heat transfer analysis can also be performed. With the help of a slow motion camera your test results are recorded.

There are models available for all THALETEC turbines, that can be assembled as one or multi stage mixing systems. Models of all most common used baffels complete the test stand.

If necessary turbine models can be made very fast with a 3D printer and ABS plastic. You receive test reports and video recordings of all results when the tests that you requested are finished. In addition we also offer flow mechanical problem solving with computational fluid dynamics, CFD for analysis and visualization.

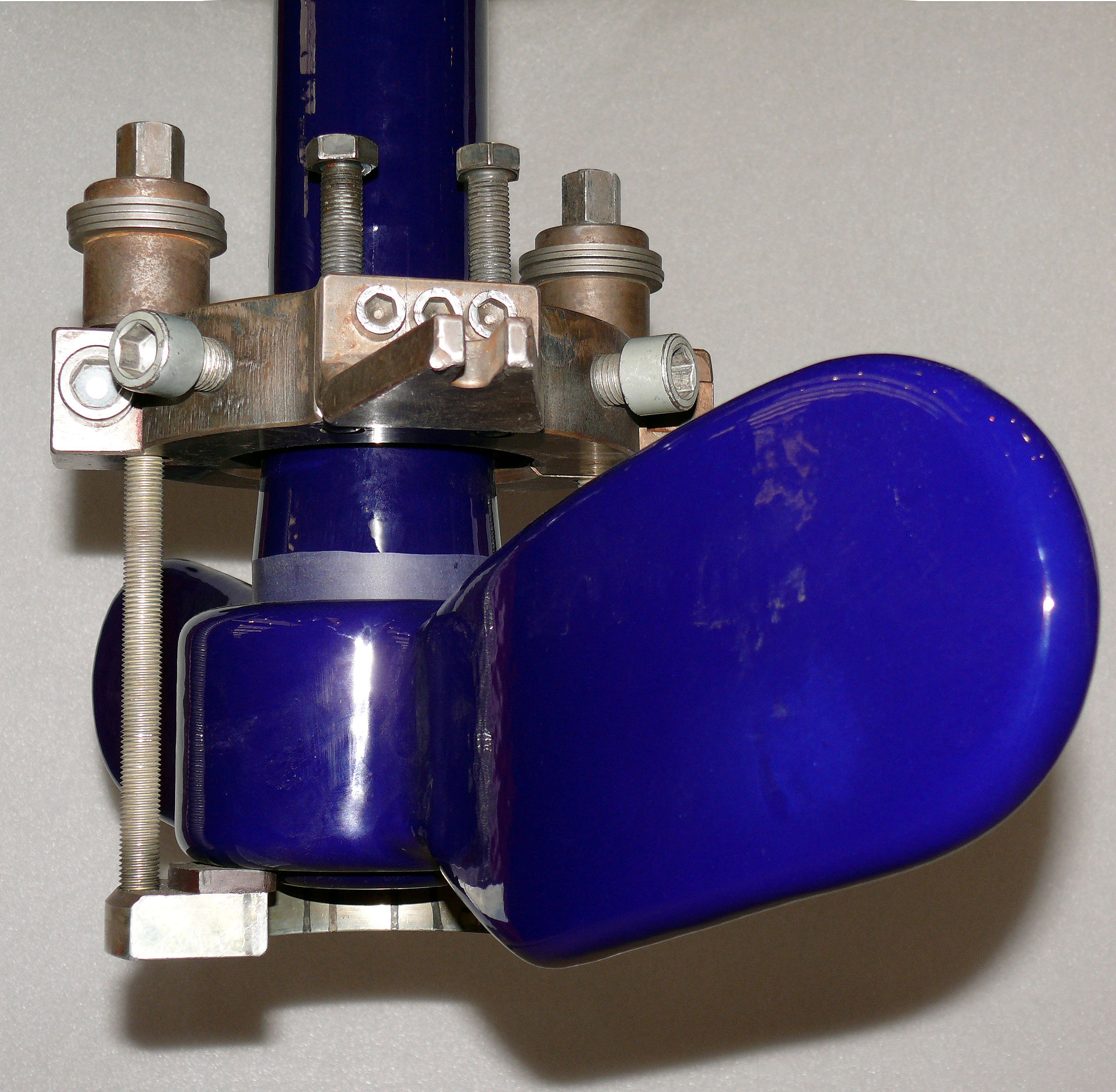

The THALETEC MultiFlex system is a proven techonology to connect different full glass lined turbines with completely glass lined shafts. Many different stirring levels can be assembled on one shaft. This enables to realize mixing systems that are adapted to a specific task delivering optimal mixing results by better economics.

Besides the standard mixing systems like the impeller turbine (RCI), the anchor turbine (ANC) and the turbo-turbine (TAF) THALETEC has developed process specific special optimized turbines. THALETEC residual material systems CXR and TAR. To meet requirements of processes we have developed a axial acting low shear and radial acting turbine with high shear that also can mix small volumes.

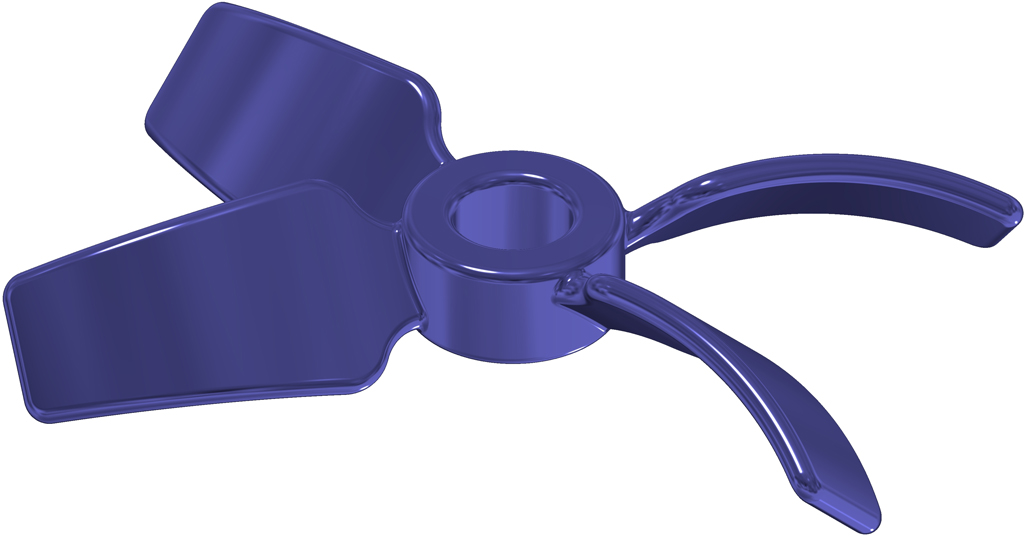

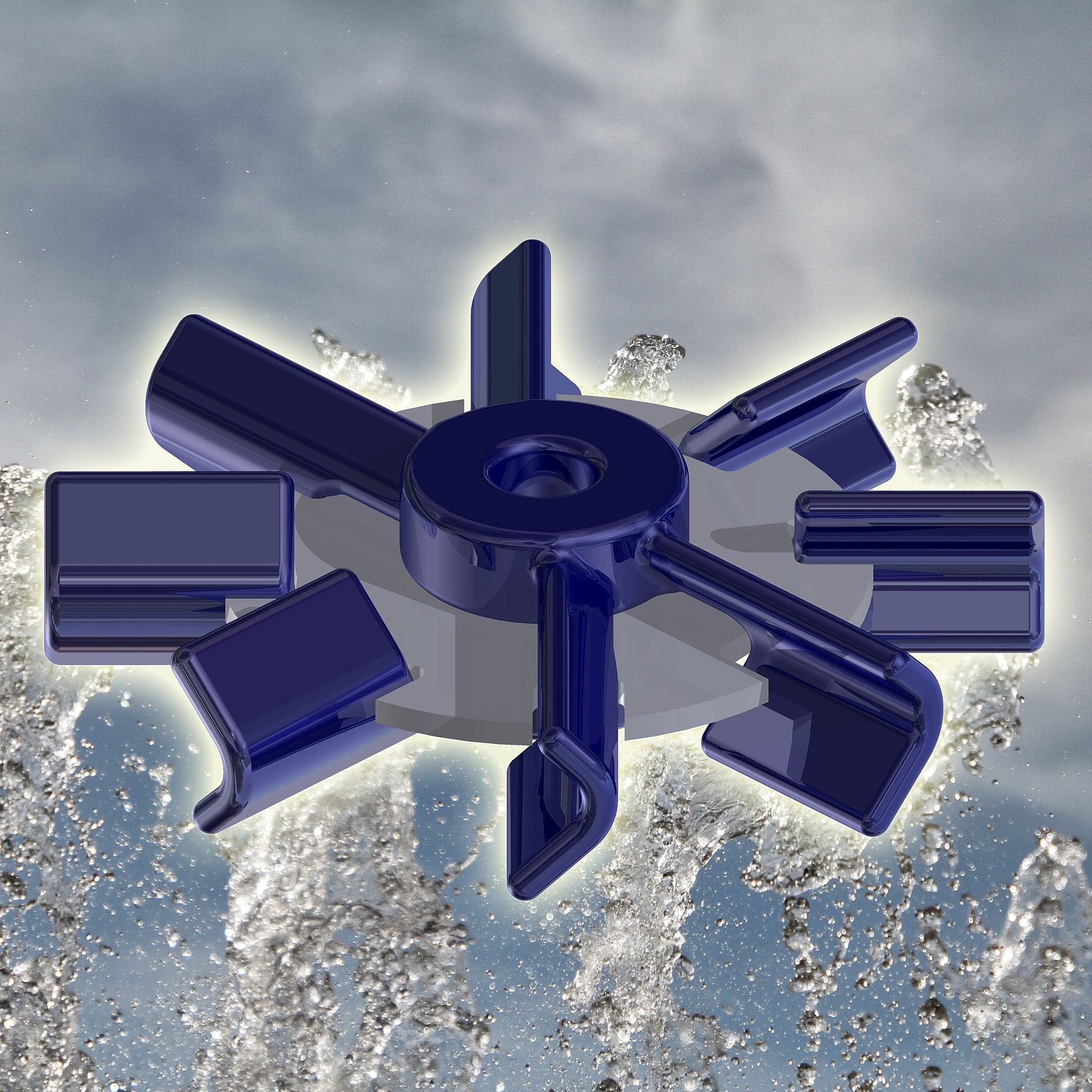

The THALETEC DCT turbine is a true multi-talent in the mixing technology. Depending on the mounting position the DCT turbine works as a "diffusor", "concentrator" or as a combination of both. Different agitation effects in a reactor are reached with the same components.

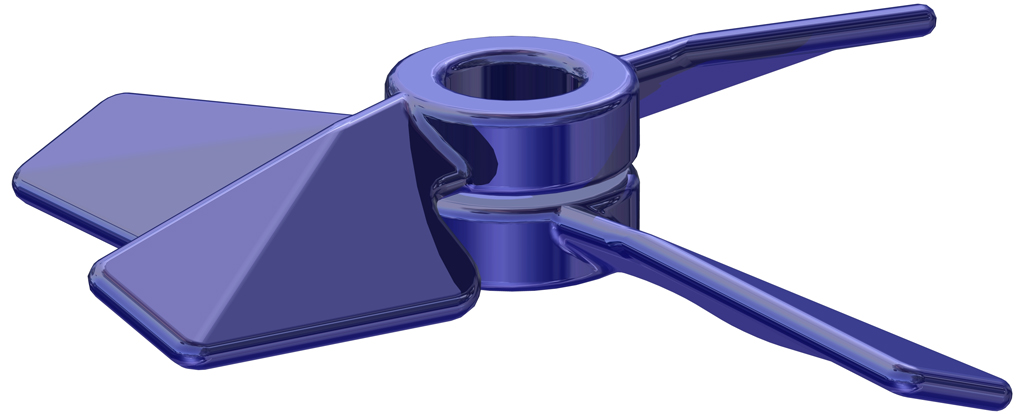

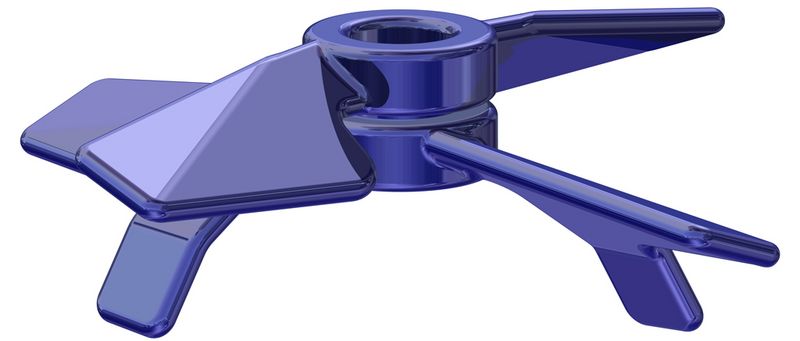

The THALETEC AMT turbine is a mainly radial acting mixing element that is used for abrasive mixing processes. The special layout together with other measures enables to reach a significant longer lifetime and increases the availability of your system. The glass lined cross arm turbine CAT from THALETEC with four cross arms (CAT: Cross Arm Turbine) are slow motion mixers, that are used to homogenize low to middle viscosity media (up to 5 Pas).

Cross arm mixing elements with a diameter from about 50 to 60% of the tank diameter offset by 90 degrees to each other are mounted on the shaft with four mounting points (other mounting numbers on demand.

The THALETEC disk turbine SGT (Smith Gassing Turbine) is a mixing element with six to eight mixing blades. There is a disk made of a thermal and mechanical stable PTFE compound assembled on the middle stage of the mixing element. The mixer is designed in such a way that it can be assembled in the reactors types AE, BE and CE acc. to DIN 28136 where the biggest tank opening is the manway.