THALETEC offers fast repair techniques and creates high standards for occupational safety!

Compared to other highly chemically resistant materials, glass-lined equipment has a low CO2 footprint and can also be re-glassed several times.

Glass-lined equipment can also be repaired on site. THALETEC repairs the damage using glass-lined repair techniques.

In this newsletter you can read about THALETEC's wide range of repair techniques and how you can increase the safety of your glass-lined equipment.

- THALETEC – Glass-lined Repair Systems

- Limits of tantalum repair kits for glass-lined equipment

- Repair Sleeves always in stock and available immediately

- Overview of services and related products

- THALETEC SafeBase – safe working in a glass-lined vessel

- THALETEC PremiumValve FireSafe

- THALETEC MultiFlex System

- Poster "Work Safety"

Limits of tantalum repair kits for glass-lined equipment

Practical experience has shown time and again that tantalum repairs on glass-lined equipment have a limited service life, even if they are checked and monitored regularly. Where does this come from? And what can be done about it? This article provides an insight and shows solutions.

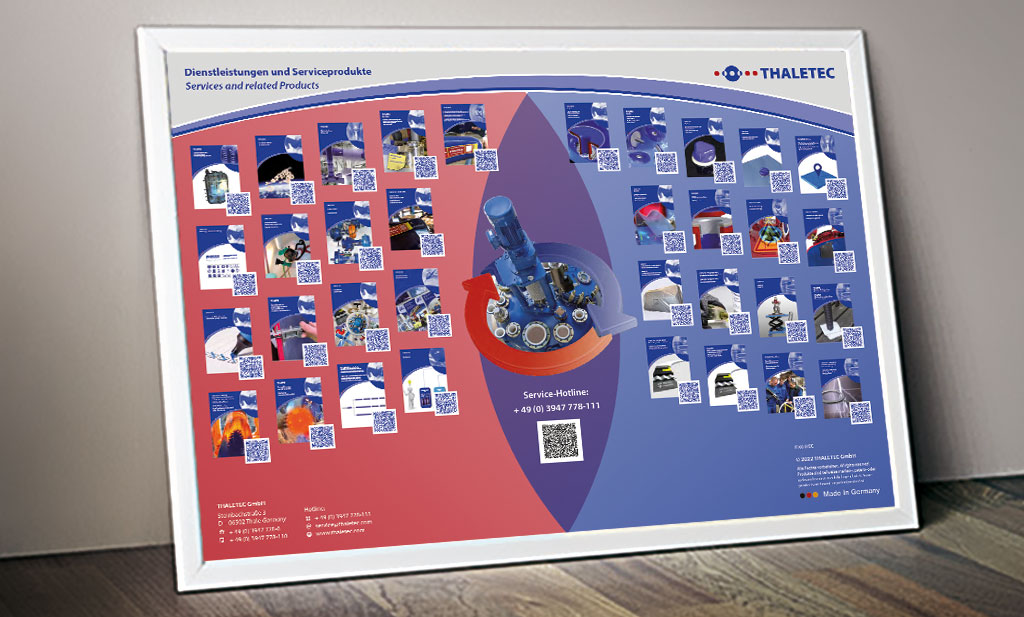

Overview of services and related products

A poster summarizes all THALETEC services around your glass-lined equipment. Request a digital copy by e-mail to process@thaletec.com or a printed version under the following link!

Poster "Work Safety"

In the new poster "Work Safety" we have clearly summarized all THALETEC solutions in this area. Request a digital copy by e-mail to process@thaletec.com or a printed version under the following link!