The second Part, ACHEMA Review Part 2, you can find here.

More of everything

All in all, we exhibited over 30 new and innovative solutions relating to glass lined equipment at the fair. Of course, THALETEC’s range is far more extensive. For example, a large-format overview poster (Flyer K035) provides an overview of all available solutions for optimising glass lined agitated tanks.

We are happy to send you the poster in A2 format too; just email service@thaletec.com. Of course, we are always available for a consultation at any time. The contact details of THALETEC Sales can be found on the website. We would also like to draw your attention to our extensive training and workshop programme (Flyer K108) in which you can train up to a high level.

As you can see, THALETEC is more than ‘just’ a supplier!

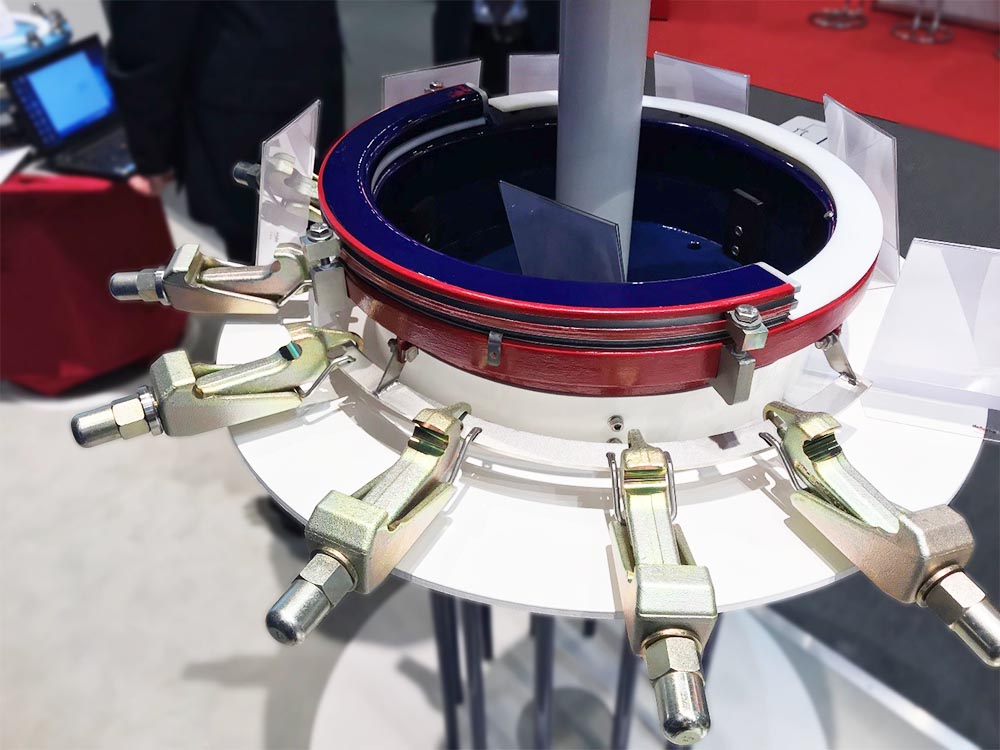

More tolerance - More tolerance when evening out flange distortions

Distortions and deformations of glass lined flanges and nozzles are production-related and can be minimised but never completely eliminated. Corresponding DIN standards specify the limit values. To ensure a secure sealing of nozzles, solutions are needed which minimise the deviations caused by flange distortion. With this in mind, THALETEC offers a variety of solutions, which we presented to the trade visitors at the trade fair stand. The best-known method is the shimming of flange gaskets with the QuickShim shimming material (Flyer K105). A self-hardening paste is injected into the sealing sheath of special shimmable seals, thereby compensating for areas of unevenness and distortion during the fitting of the seal.

Shimming with QuickShim must be performed every time the seal is changed. A permanent solution, however, is the use of ShimFree intermediate rings (Flyer K104). Here, the deformed flange is first measured and then an intermediate ring, whose contour correspond exactly to the deviations of the deformed flange, is made and glass lined. The seal between the components then no longer needs to be shimmed.

Finally, together with the company TEDIMA we exhibited the ‘3D Logic Seal’ system (Flyer K111), exclusively sold by THALETEC. In this approach, the deformed flange is also first measured. Subsequently, a sealing element is 3D-milled on the basis of the measured data. The shape of the sealing element corresponds to that of the deformed flange. In this case too, no subsequent or additional shimming is any longer required.

For optimum flange connections, of course, suitable clamp screws and loose flanges (Flyer K048) are also required, as is the appropriate thread lubricant (THALETEC SeizEx, Flyer K117).

Picture right: Exhibit ‘Evening out flange distortions’. Next to a Shimfree Ring and the 3D-Loc-Seal, a clamp screw/retaining ring is also to be seen which is for manhole openings for retrofitting and which prevents the clamp screws in the open state striking the tank floor.

Additive Manufacturing: The THALETEC TwisterMixer

The topic of additive manufacturing has meanwhile become significant at THALETEC. After several years of development work in the field of ‘Additive Manufacturing and Glass Lining’, we are now able to produce 3D-printed metal parts safely and cost-effectively, to process them and, finally, to glass line them. We exhibited some results of this development work on the stand: The static mixer THALETEC TwisterMixer (Flyer K120), in which the mixing elements were produced on a 3D printer and then glass lined, attracted attention. This makes the TwisterMixer the world's first static mixer with glass lined mixing elements for corrosive processes. We also exhibited glass lined agitators on a small scale for applications in the laboratory and in process development (THALETEC LabTec). These agitators correspond exactly in their dimensions to the large agitators for agitated tanks, so that agitation technology scale up can be performed safely and without problems.

Another example of a successful application of 3D printing is the THALETEC high-pressure reactor. The tank, including the heating/cooling channels, was manufactured additively and all areas in contact with the medium were then glass lined with strong resistance to acid. Since the base glass lining could also be dispensed with in this case, this type of reactor has outstandingly good heat transfer properties.

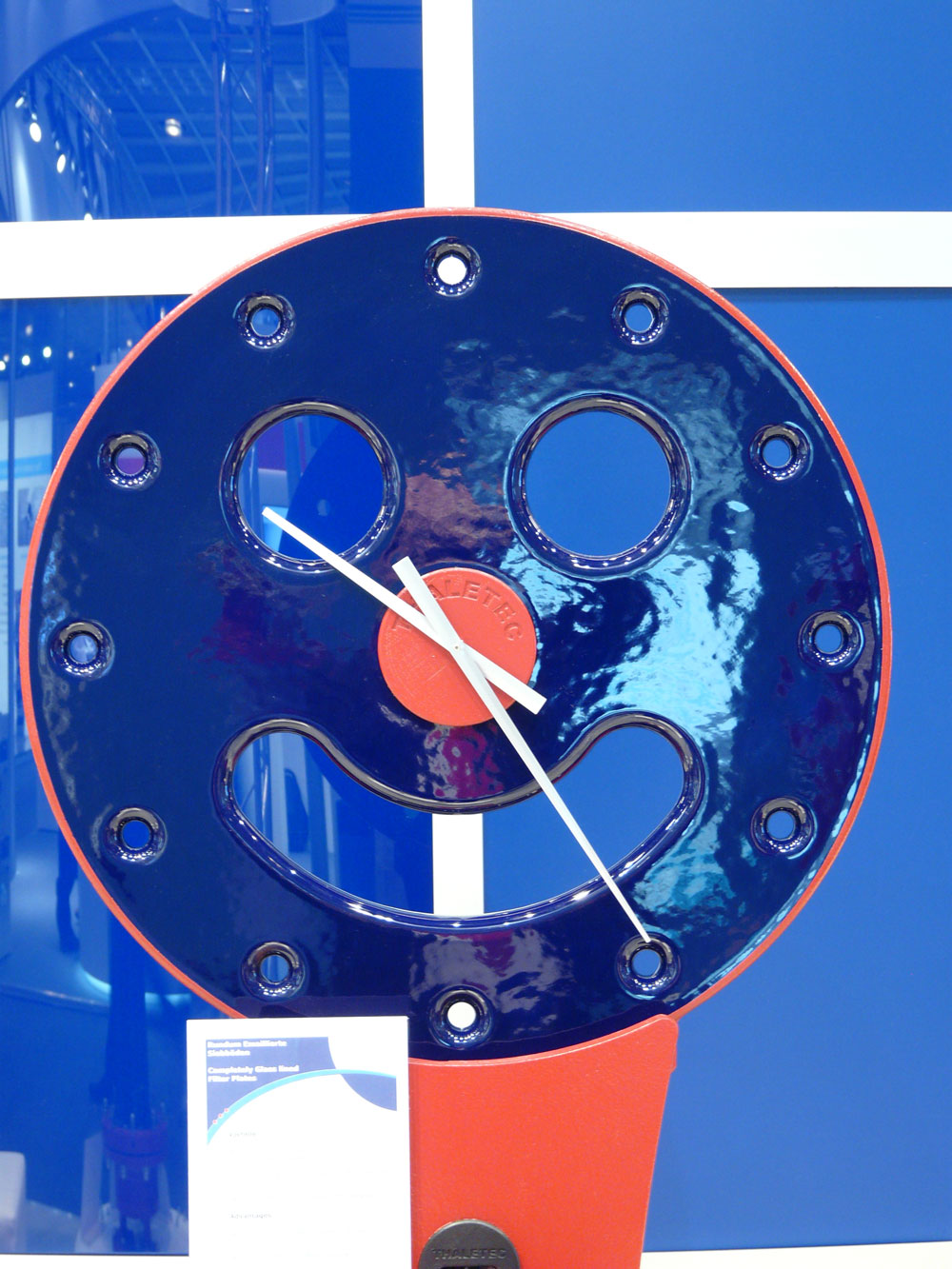

Smiley; this shows the design possibilities of intermediate floors and sieve plates in columns or pressure filters (Flyer K063).

The Smiley

Considered by many visitors to be just comic detail, the ‘Smiley’ exhibit showed everything that can be glass lined today. The smiley shows the geometric flexibility with which components, such as intermediate floors glass lined on both sides, can be executed for columns (Flyer K126). The fact that the Smiley also showed the time and served as a mobile phone charger was then only an incidental detail relating to this exhibit.

THALETEC Agitator Drive

A widely acclaimed exhibit was also the agitator drive (Flyer K015) exhibited by THALETEC, in which we presented various innovations and solutions. The ready accessibility of the shaft coupling and the easy handling of the tool shown for the assembly and disassembly of the shaft seal were assessed positively by many experts. We also showed the automatic re-lubrication system for rolling bearings on mechanical seals (Flyer K086). The exhibit was supplemented by the thermal base flange (Flyer K110), which can be actively cooled and the CIP Base Flange (Flyer K064) for the quick and safe cleaning of product-contact areas of mechanical seals. Finally, the novel and patent-pending shaft lip seal from the company EagleBurgmann, which THALETEC exclusively exhibited, attracted great customer interest.

Picture right: To the left of the agitator may be seen an example of THALETEC WePro - protective covers and protective hoods for storing glass lined equipment outdoors.

Content

Additive Manufacturing: The THALETEC TwisterMixer

More Tolerance – More tolerance when evening out flange distortions