The all-rounder rediscovered

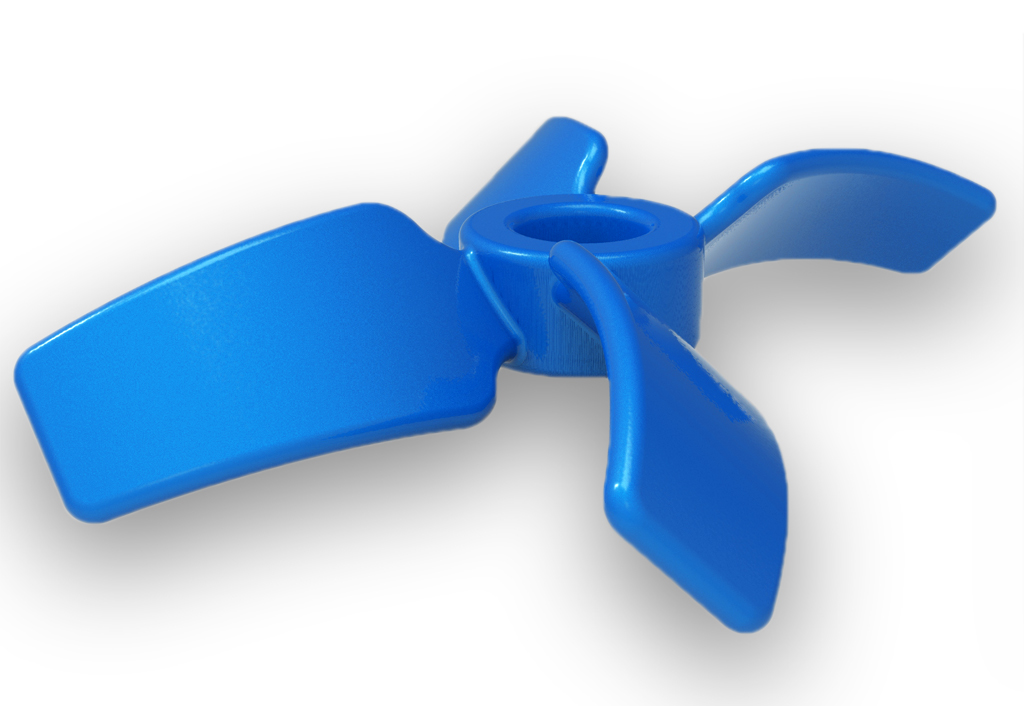

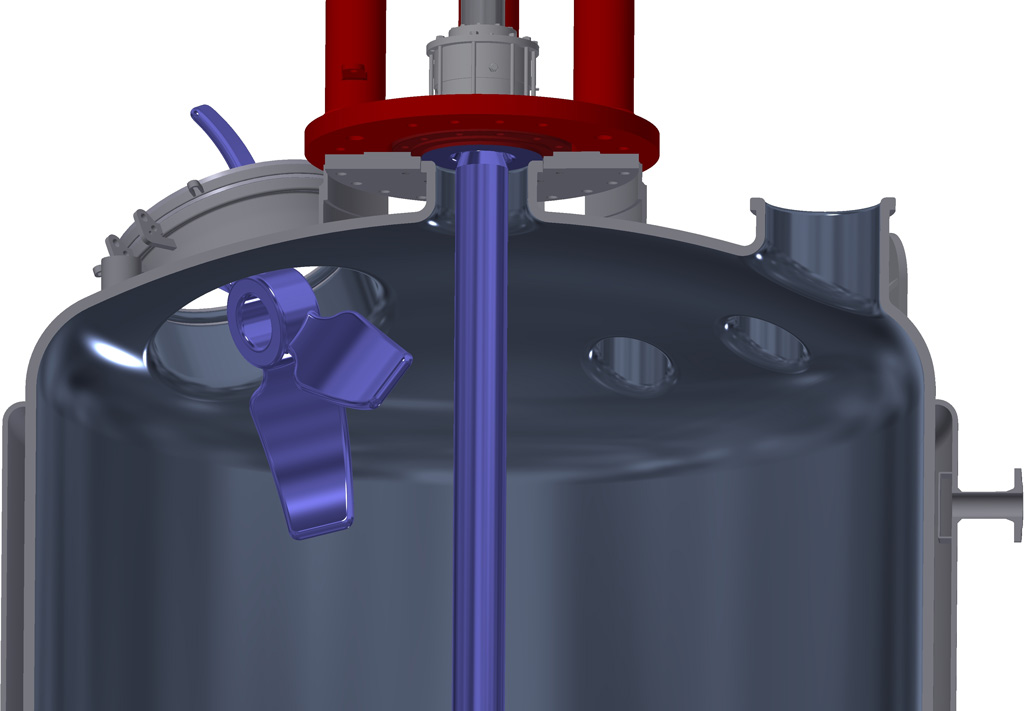

The DCX is a 4-bladed axially-promoting agitator turbine. The unique curved design of the agitator blades allows the axial flow to be brought closer to the shaft while being more resistant to abrasive processes. This turbine therefore has particularly good properties as a suspending and homogenising agitating element. The DCX is also particularly suitable as a second or third stage for feeding the lower stages or for drawing in suspended material.

The new design allows the turbine to be manufactured in one piece while still retaining the concentrator and diffuser characteristics. The concentrator arrangement, with the concave side facing down, is particularly suitable for drawing in suspended material or as a second or third stage feeder.

In the diffuser arrangement, with the concave side facing upwards, it is particularly easy to suspend and the radial flow component improves heat transfer.

By simply reversing the turbine, the different characteristics of the DCX are achieved and this is further simplified by the new design. As in the case of the TXF turbine, a more compact design was also implemented here. The blades of the DCX were mounted on a hub to simplify the manufacture of the turbine. The stirring characteristics of this turbine are not adversely affected by the simplification. Due to the curved shape of the blades and the fact that the angle of attack of 44° to 55° to each other is maintained, the turbine retains its characteristics and becomes more logistically attractive.

What are the advantages?

The DCX turbine is particularly suitable for suspension processes and homogenising. The simpler production results in many advantages for you as customers.

- Firstly, despite a different design, you receive a turbine with the same characteristics, as it has already proved itself.

- Secondly, the assembly of the turbine is greatly simplified. The fitter only has to shrink one hub. This saves time and money. At the same time, 2 blades do not need to be shrunk and repaired separately where there is damage.

- Thirdly, you only have to buy one turbine and not connect 2 blades to one. This simplifies the storage and logistics of the turbine.

- Fourthly, the turbine is becoming more attractive for pharmaceutical applications. The gap between the individually shrunk turbines of the TAF was often too great for the operators. This is now changing.