The so-called NS1 criterion is familiar from the technical literature on stirring. NS1 is defined as the agitator speed at which ‘no solid particle remains on the tank bottom for more than one second without being stirred up’. This speed is also known as the ‘Just Suspended Point’ (Schubert, Handbuch der mechanischen Verfahrenstechnik)

In order to compare different stirring systems, not only is the suspension speed NS1 relevant but also the required drive power of the agitator. Only from this, in a comparative consideration of different agitator systems, does a criterion capable of scale-up, namely the volume-related power input P/V, result.

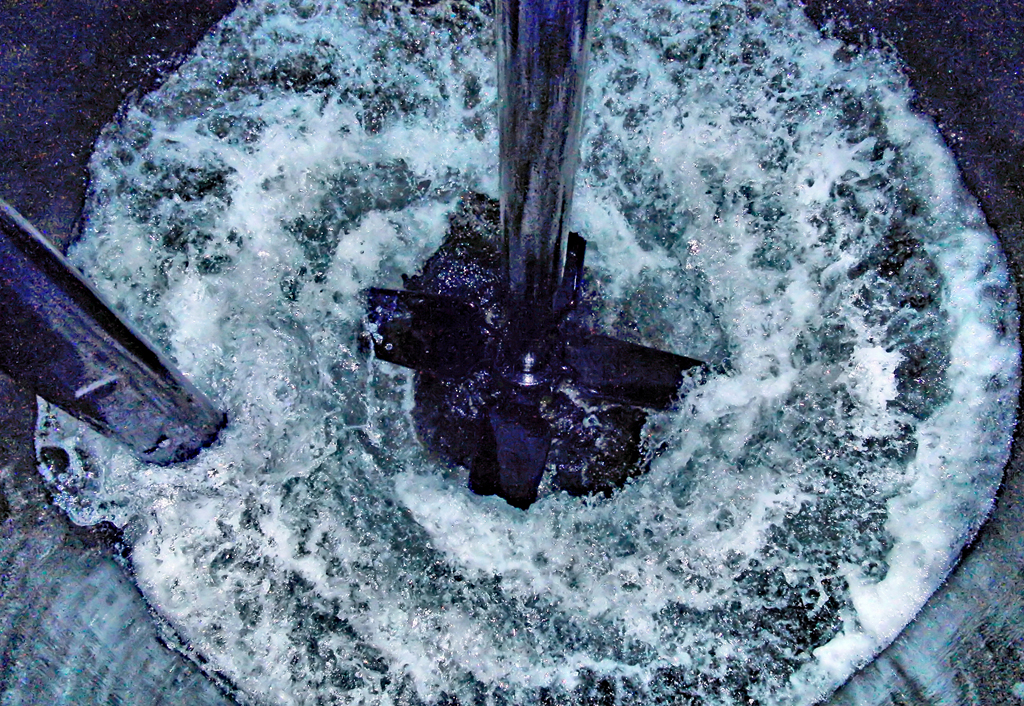

At the THALETEC agitating technical centre, different agitator systems were compared on a model scale with regard to their suspension behaviour. For this purpose, the agitator types TAF, TAR and DCX were installed in a model system and tested under the same installation conditions. With the help of modern video technology, the individual suspension states could be documented and compared on the basis of the records.

(Illustration: Agitator units examine)

Results

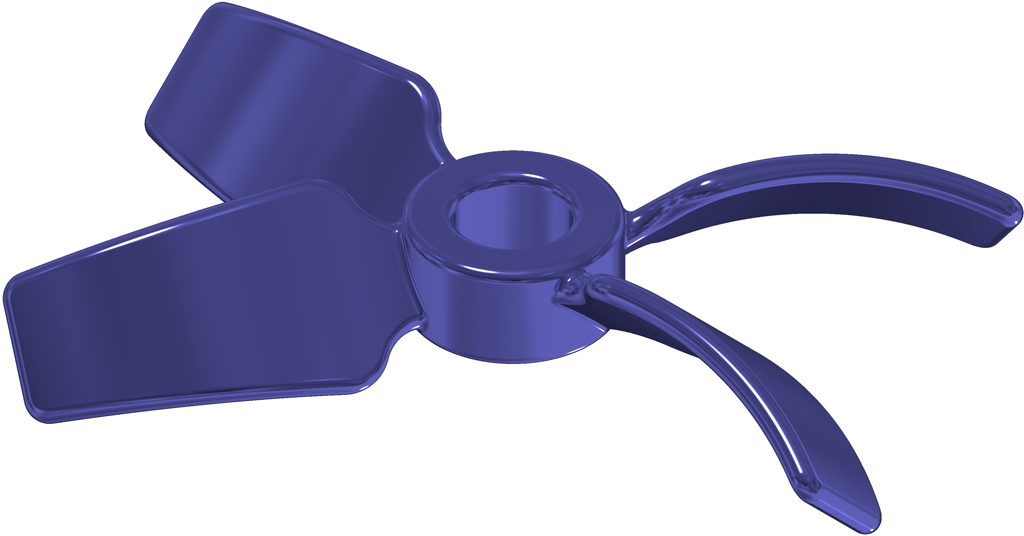

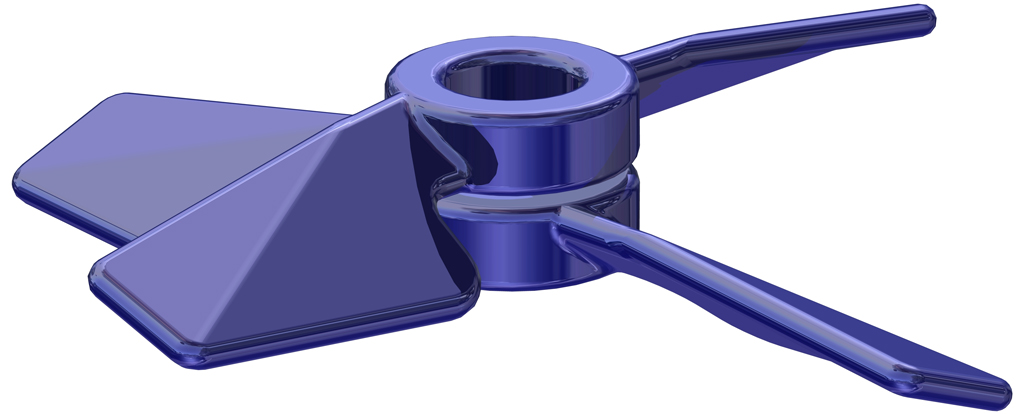

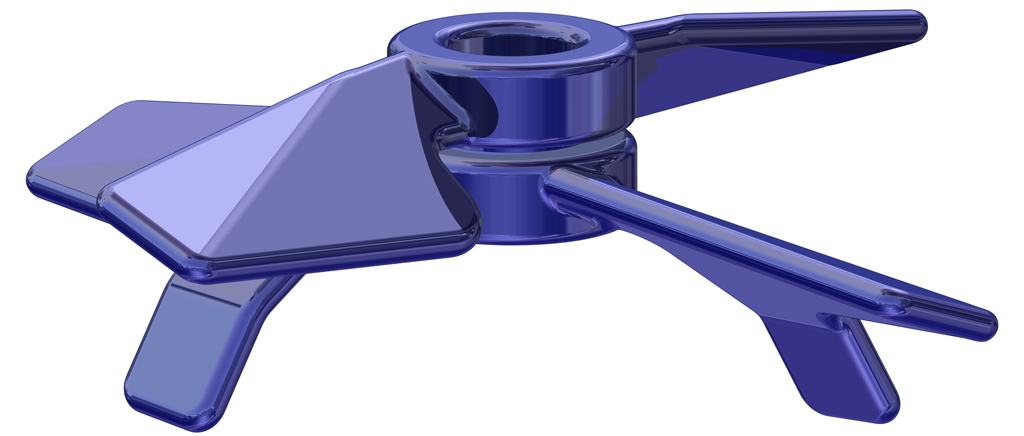

Table 1 summarises the results. It turns out that conventional axial-flow agitators such as the THALETEC TAF (a typical hydrofoil agitator) have the highest rotational suspension speed compared with other agitator units. The THALETEC DCX turbine has proved to be the agitator unit with the lowest rotational suspension speed. The THALETEC DCX turbine also shows advantages in the comparison of volume-related power inputs (P/V): If the volume-related power input of a turbofoil or hydrofoil agitator is set at 100% to achieve the NS1 criterion, a THALETEC DCX turbine requires only about 2/3 of the volume-related power under otherwise identical boundary conditions. This makes suspending with a THALETEC DCX turbine over 1/3 more energy-efficient than using the same stirring task with a TAF turbine.

Comparison of the values determined for the model system

DCX in multistage systems

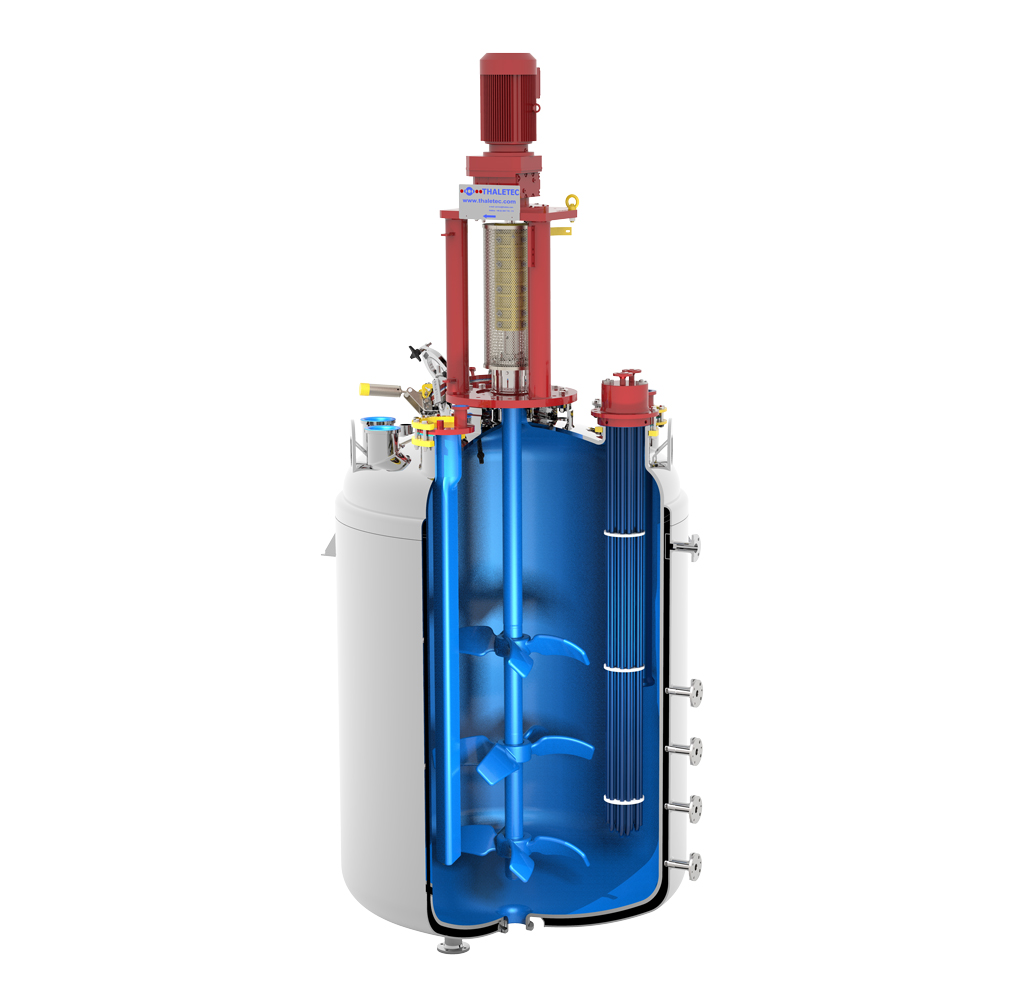

The investigations described referred to stirring systems in which a stirring plane is installed at a certain distance from the Tank bottom. A further improvement in mixing can be achieved by using multistage stirring systems. Here too, stirring systems with multistage DCX turbines have proved their worth. Illustration 2 shows such a stirring system. A three-stage agitator with DCX turbines on each level and a PowerBaffle instead of a conventional baffle ensures energy-efficient suspension of solids and good heat transfer with short heating and cooling times.

Conclusions

The suspension of solids in agitated vessels can be realised by axial-flow agitator units. However, the agitator geometry has a significant influence on how energy-efficient this is. Compared with conventional axial-flow agitators, such as typical hydrofoil agitators, the THALETEC DCX turbine is able to achieve suspension with over 30% higher energy efficiency. We therefore recommend using for suspension tasks the THALETEC DCX turbine, which is suitable for all agitator shafts with cylindrical shrink fit (e.g. Cryotec System) or the Multiflex system.