To meet customer requirements even better with a short delivery time, particularly for spare parts, THALETEC has conceived and implemented a comprehensive modular system for glass-lined agitator shafts.

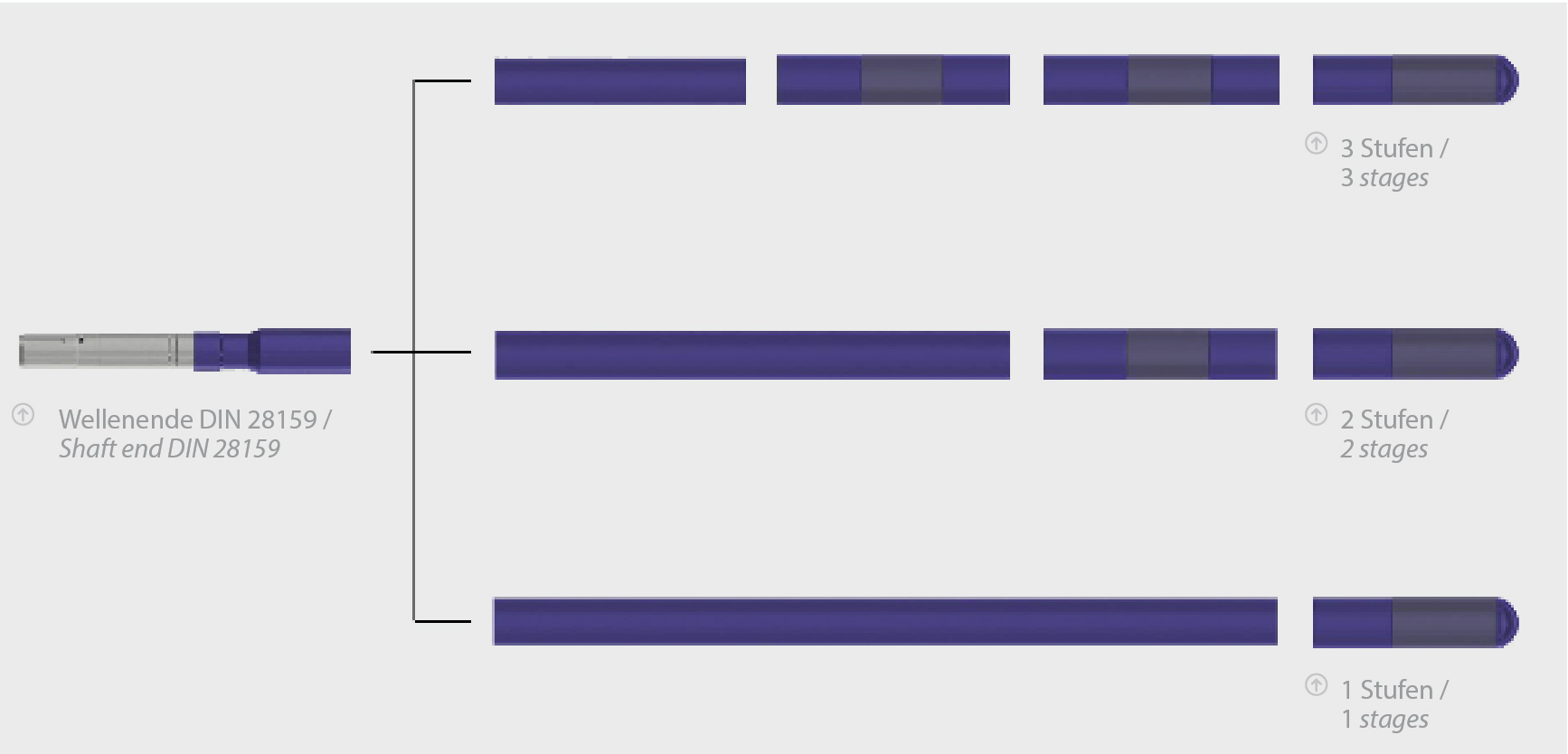

Whilst many manufacturers make agitator shafts "from one piece" and thus when spare parts are required have to run the entire production process from cutting through to machining, the glass-lining process through to polishing and finishing, THALETEC uses a modular system for its glass lined agitator shafts in accordance with DIN 28159 (see Cover):

- Agitator shaft ends according to DIN 28159 or according to the standards of other manufacturers

- Agitator intermediate pieces without a working surface which can be adjusted to the required length, if necessary

- Agitator intermediate pieces with a

- CryoTec or Multiflex working surface

- Agitator end pieces with a CryoTec or Multiflex working surface

All modules are manufactured independently of each other and are kept in stock. When ordered, the individual modules are adjusted, as necessary, assembled and, using the LocaRep process (see Flyer

K112), the glass coating is applied locally to the connection points so that the resulting agitator shaft meets the customer's requirements exactly.

In this way, the following can be individualised:

- Diameter of the agitator shaft (components for shafts 80 (3''), 100 (4''), 125 (5'') and 140 mm (6'') are available as standard)

- Length of the agitator shaft

- Type of the connection between agitating element and agitator shaft (CryoTec or Multiflex)

- Number of agitator stages (up to three stages)

- Distances between the individual agitator planes

"Fast shafts" are designed in the universally applicable RAS GLASS blue and are exchangeable at any time and compatible with agitator shafts of other manufacturers.

A special process to align and level the agitator shafts guarantees minimal concentricity tolerances. In particular, the concentricity tolerances in the area of the mechanical seal in accordance with DIN 28161 in most cases are well within the permitted range.

Following clarification of the parameters and the task in hand, THALETEC can manufacture such agitator shafts usually within a few working days.

Of course, THALETEC also offers the appropriate agitating elements for the agitator shafts. A number of sizes and designs of these are available at any time and in stock. Please request if required!