Significance of electrical conductivity

Corrosively stressed process equipment in the chemical industry is often glass-lined. Technical enamel is in principle a chemically highly resistant glass, which is fused homogeneously and pore-free with a carrier material, in chemical apparatus usually a fine-grained structural steel. The glass-ling meets the highest requirements for chemical resistance and quality: The apparatus and components manufactured by THALETEC are manufactured and glass-lined in accordance with ISO 28721 2. The enamels easily meet the requirements for resistance to acids and alkalis according to ISO 28706.

More recently, operators are paying more and more attention to safeguarding equipment when there is a risk of electrostatic charging. Enamels, like all glass, are usually non-conductive.

Non-conductive surfaces, however, harbor certain plant risks, especially in the case of electrostatic effects. Most of these can be safely minimized by inerting the equipment.

However, the risk of damage to the enamel layer has remained. Damage is the result of electrostatic discharges, whereby a spark penetrates through the (non-conductive) enamel coating onto the base body (steel), perforating the insulating enamel layer and thus damaging it.

Depending on corrosive stress, such punctual damage can quickly turn into capital damage such as breakthroughs and the associated consequential damage to the system.

THALETEC has developed the electrically conductive enamel "Condusist" (Flyer K098), a solution for such problems, which has been used by customers worldwide for many years. Condusist is an electrically conductive glass-lining. Semiconductor ceramics are embedded in the amorphous glass matrix to form a 3-dimensional, dissipative network within the enamel layer. This catalytically ineffective network provides an electrically conductive enamel layer so that the risk of breakdowns is minimized. Another positive aspect is that Condusist, like all other THALETEC enamels, meets the durability requirements for high-quality chemical enamels. This means that the operator does not have to make any compromises with regard to the fields of application of glass-lined process equipment.

Important: Conductive Stirring

THALETEC introduced Condusist in 2015 and has since manufactured and supplied several hundred agitator vessels and components for agitator vessels such as agitator shafts, agitators, baffles and bottom outlet valves (see also newsletter article).

Condusist electrostatics can help to avoid risks, especially with stirring vessels, because high charges due to strong charge separation processes occur during the stirring process when the non-conductive media are intensively mixed.

Just as important: conductive storage

In practice, however, there are also electrostatic risks in glass-lined tanks which are used exclusively for the storage of electrically non-conductive liquids. Why is this the case when it can be assumed that "storage" essentially concerns "static" liquids? Well, tanks must also be filled and emptied. During these processes, areas of high fluid velocities can occur, just as during stirring. However, high velocities can indicate charge separation and thus the formation of local electrostatic charges in the fluid. Such high velocities can occur in particular when emptying tanks. An example calculation illustrates this:

A vertically standing glass-lined storage tank with a height of 5 m is filled with a liquid. The liquid is to be emptied via a bottom outlet. According to Toricelli's law [1], the outflow velocity v depends exclusively on the filling level of the tank and follows the law of

v=μ⋅√(2⋅g⋅h)

Where μ is the discharge coefficient (approx. 0.6 to 0.7 for water-like substances), g is the acceleration due to gravity and h is the respective filling level of the container.

If the values are inserted into the equation, a maximum outflow velocity of 6.9 m/s is obtained for the given tank! According to [2], however, flow velocities of up to 7 m/s are only permissible in exceptional cases. Rather, it applies that" (...) single-phase liquids are (are) not dangerously charged by flow velocities of up to 1 m/s in conductive, earthed pipelines". Conversely, however, this means that higher flow velocities during emptying may well lead to charges which could break through the enamel and thus damage it. Since these damages are then preferably in the area of the outlet nozzle, a repair with THALETEC RepSets is in principle possible (see e.g. Flyer K095), but is associated with high costs and often time-consuming.

THALETEC therefore recommends that the additional safety provided by an electrically dissipative enamel coating should not be compromised, especially with glass-lined storage tanks and templates.

Use the correct flange gaskets!

Flange gaskets which are also electrically conductive and whose metal inserts can be electrically earthed should always be used for nozzles of electrically dissipative glass-lined process equipment. In [3] the following is said about this:

"In conductive lines, all metal inserts in PTFE gaskets must be earthed regardless of the nominal diameter DN, unless it can be proven that dangerous charges are not to be expected. The reason for this is the much higher capacitance due to the installation method ("double plate capacitor") compared to the seal not installed.

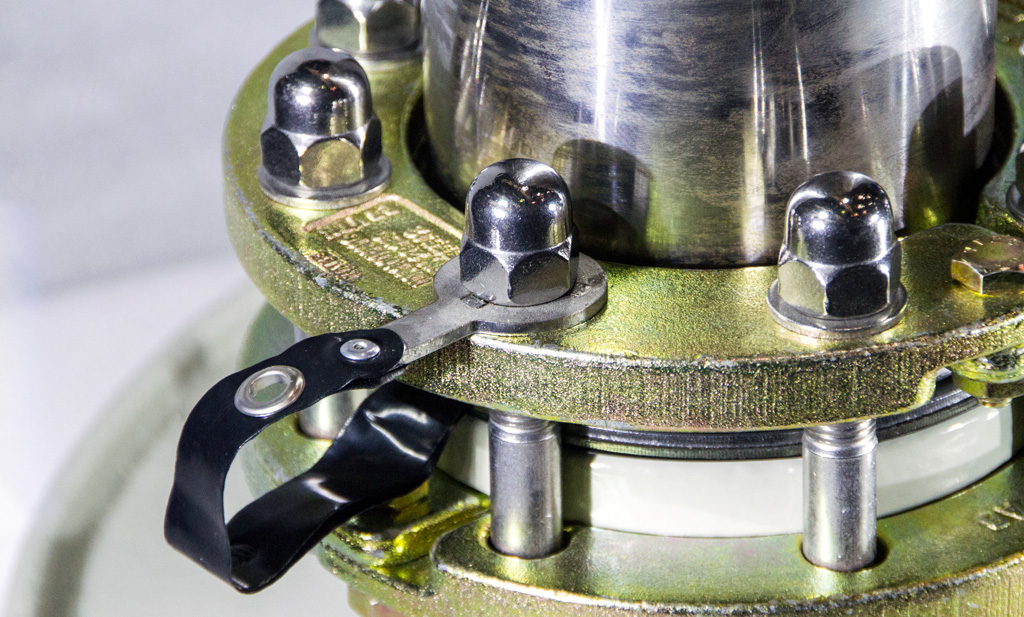

For the earthing of metal inserts in PTFE gaskets, metal inserts with earthing straps have proven themselves in practice."

Electrically conductive flange gaskets of the Conduseal design (Flyer K100) consist exclusively of conductive materials: A sealing sheath made of conductive PTFE encloses soft material inserts which are also conductive, e.g. contain or consist of graphite. Furthermore, such seals have earthing lugs which can be attached to nearby metallic and earthed components and thus discharge electrical charges (see illustration).

Literature

[1] Wikipedia, Gesetz von Toricelli zur Ermittlung der Ausflussgeschwindigkeit aus Behältern: https://de.wikipedia.org/wiki/Ausflussgeschwindigkeit, abgerufen 27.11.2019

[2] Berufsgenossenschaft Rohstoffe und chemische Industrie, Website „Ex Schutz Wissen“, https://www.bgrci.de/exinfode/ex-schutz-wissen/antworten-auf-haeufig-gestellte-fragen/elektrostatik/331-mit-welcher-stroemungsgeschwindigkeit-darf-ein-tank-mit-brennbaren-fluessigkeiten-befuellt-bzw-entleert-werden/, abgerufen am 27.11.2019

[3] Berufsgenossenschaft Rohstoffe und chemische Industrie, Website „Ex Schutz Wissen“, https://www.bgrci.de/exinfode/ex-schutz-wissen/antworten-auf-haeufig-gestellte-fragen/elektrostatik/712-muessen-metalleinlagen-in-ptfe-dichtungen-in-fluessigkeits-leitungen-geerdet-werden/, abgerufen am 27.11.2019